Wiped Film Evaporator for the Distillation of Cardanol from Cashew Nut Shell Liquid

30 March 2021

Wiped Film Evaporator for the Distillation of Cardanol from Cashew Nut Shell Liquid

Industry: Fine and Specialty Chemicals

Case Study Introduction

Before a commercial scale production facility can be designed, the process must first be developed and optimized.

Most processes are developed in the lab and then process simulation software is used, incorporating the lab data, to model a commercial scale facility.

Where pilot testing is possible, it is ideal to collect real-life data at pilot scale rates and then to use this data for direct scale calculations and for checking or enhancing the process simulation.

Pilot testing is also utilized to collect data and to use it to design process improvements to increase the yield of the existing process and/or to improve the purity of the product produced.

GMM Pfaudler Group has always promoted pilot-scale trials for critical applications to confirm the performance of its technologies and to collect data for commercial scale-up.

Pfaudler’s commitment to this approach can be demonstrated by hundreds of cases for different applications and various market sectors.

One such example is of a fine and specialty chemicals manufacturer which produces Cardanol.

Cashew Nut Shell Liquid (CNSL) is a raw material which is a source of a fine chemical called Cardanol. It is extensively used for making resins, coatings, frictional materials, etc.

Our task was to prove to the customer that a Pfaudler Wiped Film Evaporator (short path type) could be utilized to increase the yield of Cardanol compared to the client’s current method of utilizing conventional reactor batch vacuum distillation.

Establishing The Process

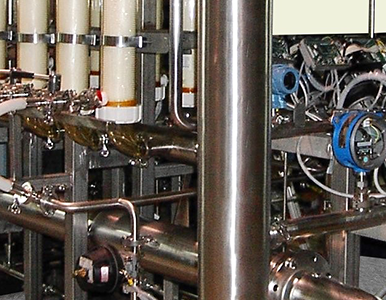

Pfaudler’s mobile pilot Wiped Film Evaporator (WFE) unit was sent to the customer’s site to perform the trials to prove the concept and collect data for scale-up.

The following steps were taken by Pfaudler engineers:

- A pilot scale (0.4 sqm) WFE was sent to the customer’s site

- Our team of engineers helped the customer with the WFE setup to ensure appropriate services (vacuum, cooling water, heating oil) were connected.

- Commissioning of the system was carried out under our technical supervision

- Several trials were completed using a matrix of various operating conditions to collect as much data as possible, and to establish the optimum operating conditions

Results

The trials were completed successfully with extensive data collected. The tests and data proved that using the Pfaudler WFE for the distillation of Cardanol from CNSL improved the yield, as expected, compared to the customer’s batch distillation method. However, the tests also demonstrated that the Pfaudler WFE also improved the purity of the final product.

Pfaudler and customer engineers reviewed the data to decide on the optimum operating conditions and used the data to scale-up a design for the commercial scale plant.

Key results and the benefits of using the Pfaudler WFE are highlighted below:

- Utilizing the Pfaudler WFE improved yield from 60% to 67% (average) and 70% (peak).

- The continuous process using a Pfaudler WFE reduced residence time and heat history of the Cardanol, which improved product purity and avoided product polymerization in the reactor.

- Utilizing the Pfaudler short path type WFE allowed high vacuum operation, which reduced operating temperature and prevented thermal degradation.

- The short path WFE has an internal condenser, which reduced the overall footprint and cost of the plant.

- Based on the results, the customer converted their commercial production reactor batch process to a continuous Pfaudler WFE.

Conclusion

Pfaudler’s Wiped Film Evaporator is an ideal solution for difficult separation processes as it improves yield and purity, that in turn, provides our clients with more efficient processes that improve their profitability.

There are many applications for Pfaudler WFEs, not limited to any industry.

Applications range from food extracts to used lube oil refining, from pharma solvent recovery to polymers, from nutraceuticals (vitamins) to biofuels.

The WFE is a problem-solver which is ideal for applications where there is a requirement for molecular distillation based on volatility, especially where the process involves products which are heat sensitive, have high boiling points, are viscous, or tend to foul heat transfer surfaces.