LowStress™ 衬里

Edlon - Fluoropolymers

Technologies

Edlon Pure-FusionTM LowStressTM 系列是为在高温下高应力抗裂而开发

Conventional industry fluoropolymer liner construction incorporates highly stressed areas in the liner.

This makes them vulnerable to stress cracking in severe hydrogen halide services at elevated operating temperatures.

Edlon® developed its PureFusion™ welded loose liners in a LowStress™ design, in order to overcome the issue of high temperature stress cracking. This significantly prolongs the lifespan of the liner under high thermal loading and highly aggressive environments.

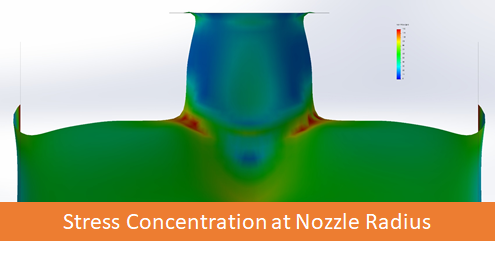

由于管口和衬里的几何形状,它们之间的接点所受的应力更高。对于任何类型的材料设计都是如此。

In typical industry lining fabrication, welds are located at the nozzle intersections which are areas of high geometrical stresses.

In contrast, with PureFusionTM lining design, the pure-fusion welds are located far from areas of high stresses.

In our exclusive design, the loose liner will be fabricated to line the full face on each of the body flanges and to line the raised face on all other nozzles.

- 机器熔焊——无角焊

- 无高应力的焊接区域 0° 半径

- 全熔透焊缝

- 不改变衬里厚度可使接头弯曲,从而使应力最小化

- 易于检查焊缝缺陷

- 手焊管口连接

- 焊接在半径 90 度范围内的工件

- 部分熔透焊缝

- 防止衬板弯曲的多道焊接——更高的应力

- 难以检查焊缝缺陷

Where operating at temperatures over 100°F, Edlon recommends using the LowStressTM design where all nozzles and manways are stress-relieved.

When combined, both technologies ensure an increased lifespan for the liner in hot HF and other aggressive services.

Edlon®PureFusionTM 管口焊接

宽松衬里中,Edlon®PureFusionTM 管口焊接至衬里主体。留意远离高几何应力区域的光滑熔焊焊缝的位置。采用同样的方法来焊接阀体法兰(左下)。

这可实现自然弯曲和应变,消除应力梯级,最大限度地减少应力开裂的几率。在 LowStressTM 设计中,在焊接前管口预应力被消除。