Wiped Film Evaporators, the problem solver for your difficult separation

09 May 2017

Wiped Film Evaporators, the problem solver for your difficult separation

Pfaudler has been manufacturing Wiped Film Evaporators (WFEs) since the 1950’s with installations throughout the world in challenging applications ranging from food to radioactive waste and everything in between.

A WFE is a thin film evaporator specifically designed to handle the most difficult evaporation requirements including the following:

Heat Sensitive Products

Viscous Products

High Fouling Products

High Boiling Products.

WFEs are fabricated in stainless steel, duplex stainless steels, nickel alloys, and other code materials, but are also available in glass-lined steel construction.

How Does a WFE Work?

The WFE is a jacketed vertical vessel with an agitator. The feed enters the top of the WFE and the rotating distributor delivers the feed evenly to the heat transfer wall. Wiper blades spread the feed to a thin film and pump the fluid down the heat transfer wall. A portion of the feed vaporizes and passes radially inward through a rotating entrainment separator which removes entrained liquid from the vapor stream. The vapors condense on the internal condenser located in the center of the WFE and the condensed material flows down the tubes to the exit at the bottom of the WFE. Any material that does not condense is discharged from the vapor outlet. The material that does not vaporize flows from the bottoms outlet.

Benefits of the WFE:

• Minimizes thermal degradation

• Higher product yields

• Improved color/odor

• Improved separation

• High vacuum operation

• Improved heat transfer

• Minimal fouling.

Applications for the WFE

WFE’s are operating in hundreds of applications around the world in the four categories listed above (products which are heat sensitive, high viscosity, high boiling or fouling).

A few typical applications are listed below:

• Omega 3 (fish oil)

• Isocyanate reduction in prepolymers

• Oil re-refining

• Biodiesel

• Ethanolamines

• PTMEG

• Purification of “Green” chemical

• BDO – Styrene Monomer

• Fatty Acids

• Paraffin / Petroleum Waxes

• VOC Reduction in Polymers

• Vitamin E Tocopherol

• Solvent Recovery

• Oleochemicals, Triglycerides.

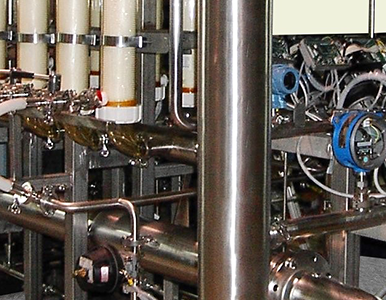

Pilot Test Facility

Pfaudler's Process Test Facility is ideally equipped to test and perfect your process; utilizing: Wiped Film Evaporators, Flash Evaporators, Distillation Columns, Reactors, and Dryers, in stainless steel, and glass-lined steel materials of construction. We perform evaporation pilot studies to prove the performance of our WFEs and to determine optimum operating conditions and to collect data for scale up to commercial production. Pfaudler's engineering team will design and build an efficient, safe, and economical commercial production facility.

Contact Pfaudler today to learn more.