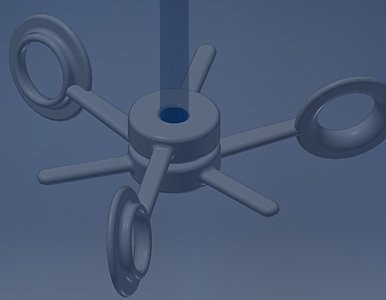

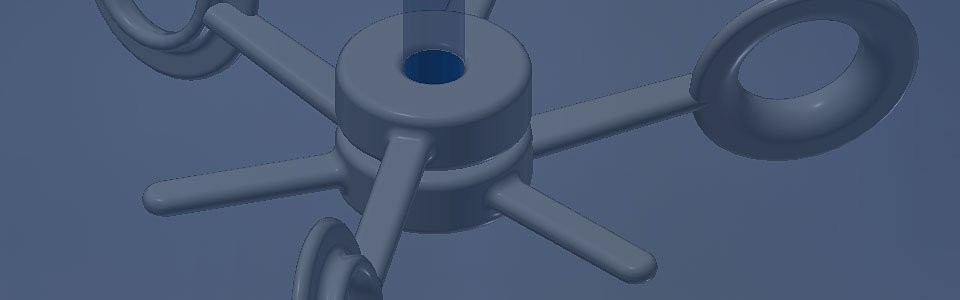

The Disc Turbine use the Bernoulli effect for accelerating the mass flow crossing the glass lined rings.

23 January 2017

The Disc Turbine use the Bernoulli effect for accelerating the mass flow crossing the glass lined rings.

The mixing process in a batch reactor greatly affects product quality and operating cost. Supported by decades of research and development, pilot testing and real-world application, Pfaudler is designing high performing, highly efficient and cost effective mixing technologies.

Each chemical process is unique and requires a different mixing design. Whether your process is liquid/liquid mixing, solids suspension, high viscous or gas dispersion we provide the solution.

Round shapes are essential for a save and durable glass lining. However, the shape of the Pfaudler Disc is not only a round one; the turbine is using the Bernoulli-effect which is accelerating the mass flow crossing the glass lined rings. Classical turbine blades are accelerating liquids by pitches and angles. The Pfaudler Disc is stirring the vessel content more gentle with less contact between rotating blades and liquid.

Treatment of products is very smooth and in case of low revolutions / tip speeds, which are recommended for this design, the disc is preferred for suspending, homogenizing, especially shear-sensitive products. The mixing forces will not destroy molecules or gas bubbles. This is because of low shear and low/med. energy dissipation.

The velocities on the wall are not differing significant compared to other turbines so the heat transfer coefficients will not be higher or lower.

In case of high viscosities, multi stage designs are recommended because in case of singe stage designs the flow on top is poor (as known from all other designs of turbines). The limit of single stage design will be roundabout 20 Pas. Multi stage designs can operate up to 50 Pas. In addition, combinations with standard turbines are possible and must be customized depending on process conditions.

Baffling effect can be very low or with low disadvantages also zero. Other vessel geometries like cubes or basins can be treated.

Bottom clearance is higher because of the disc design but also attachable by the well-known Cryo-Lock or forthcoming CryCo lock technology.

A wide range of basic research in classic glass lab vessels and with CFD (Computational Fluid Dynamics) is finished and works standard equipment for vessel BE series is available now.

We have many impeller technologies including pitched blade, curved blade and vertical blade turbine, turbofoil, gas dispersion turbine, anchor and helical ribbon designs, each performing a different function for a specific process in single flight or multiple flight configurations.

Pfaudler Disc benefits:

• Homogenization

• Operation with or without baffles (no death zones at higher viscosities)

• Solid suspension, especially crystallization

• Low shear / gentle treatment

• No foam, no gas introduction from top

• Low energy consumption, low necessary speed

• Easy to clean

• Low torque moments and forces on gear.