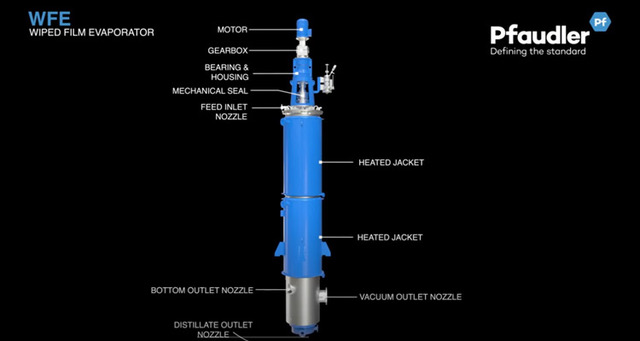

Wiped Film Evaporators

Systems

Overview

Evaporation applications that involve high boiling points, high viscosity, heat sensitivity or fouling products can be troublesome. GMM Pfaudler’s extensive experience and expertise in this area and our EQUILLOY brand Wiped Film Evaporators (WFE) are the solution.

The Wiped Film Evaporators (WFE) are designed to continuously separate volatile compounds by introducing a mechanically agitated thin film of feed material to a heated surface for efficient and reliable processing of a wide variety of products. WFE’s operate under high vacuum in order to reduce operating temperatures for high boiling and heat sensitive products. The short residence time minimizes the heat history to prevent thermal degradation. Special WFE designs provide for efficient processing of viscous materials like polymers and resins. The wipers continually clean the heat transfer surface making the WFE ideal for fouling applications

WFE Design Features

The operating features of our WFEs, such as high vacuum (short path) distillation, short residence time and a highly agitated thin film of feed product on a heated surface, makes WFEs ideally suited to handle a wide range of heat sensitive, high boiling, fouling, and viscous materials.

With WFE sizes ranging from 1.2 sq. ft. (0.1sqm) to 500 sq. ft. (46.5sqm), no application is too small or too big for our capabilities. Each of our Wiped Film Evaporator is thoroughly tested and inspected prior to shipment via Factory Acceptance Testing including a vacuum rise test, internal and jacket hydrostatic pressure test, and a operational test with water to ensure the WFE is operating precisely to our standards prior to shipment.

Technical features

Wiped Film Evaporator Systems

GMM Pfaudler Systems engineers design and supply EQUILLOY brand Wiped Film Evaporators (WFEs) as part of a complete system. For optimal performance, they will address all design aspects, from utility flow requirements to complete vacuum system integration. Our focus is on providing the most efficient and reliable overall system to achieve optimal performance from your WFE.

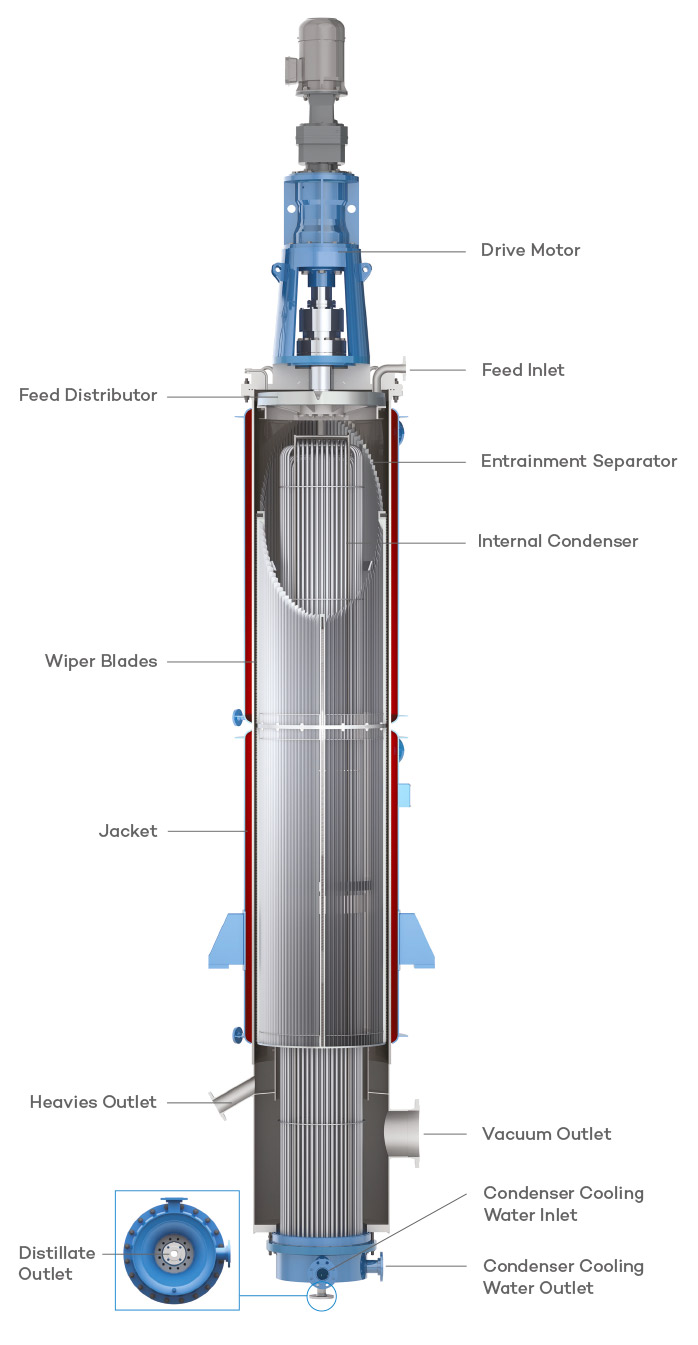

Pressure Vessel Design

Our EQUILLOY brand Wiped Film Evaporators are designed and manufactured according to most major worldwide pressure vessel codes. Adhering to strict rolling tolerances and a polished inner shell surface ensures excellent wiper blade performance and maximum heat transfer, leading to an optimized evaporation rate and separation. The jackets are also specially designed to maximize heat transfer.

Drive Units

The robust drive and large diameter drive shafts allow the rotor to be an over-hung design, which requires no bottom bearing. This design enables our WFEs to be supplied with an internal condenser which provides true short-path distillation and, therefore, minimized pressure drops and lower cost. Furthermore, while our durable shaft seal offers many years of service life, when it does require maintenance, the drive is designed for easy mechanical seal replacement without the need to remove the drive or rotor.

Entrainment Separators

The entrainment separators in EQUILLOY brand WFEs prevent entrainment of liquid in the vapor phase, which is critical for product purity and yield. We offer a range of different types of entrainment separators, depending on the process parameters required, such as vacuum level and evaporation rate. All of our entrainment separator designs provide for a high vapor flow rate even at low pressure drop and vacuum levels down to 0.001 Torr.

Internal Condensers

The internal condensers in EQUILLOY brand WFEs allow for true short path evaporation (molecular distillation) to improve separation. Our internal condensers are designed to minimize pressure drop which allows for lower operating pressures and, therefore, lower operating temperatures. With an internal condenser, project costs are reduced, as it eliminates the need for large diameter vacuum piping and all associated piping, installation, supports, and insulation costs.

Wiper Blades

Our uniquely designed wiper evaporator pump and agitate the feed material down the heated wall of the WFE with the typical length of residence time measured in seconds. In addition to this, the thin film produced by the blades greatly improves heat transfer and evaporation rate. We offer several blade designs and materials of construction, depending on the operating conditions, such as temperature and viscosity.

Unique WFE Design Advantages

Slotted Wiper Blades

Unique wiper blade designs effectively spread the material in a thin film on the wall for better heat transfer. Blades move the product down the heated wall in matter of seconds to minimize residence time.

Low Rotor Speed

High rotor speeds are not necessary with EQUILLOY WFEs. The high heat transfer coefficient, provided by the WFE design, requires lower rotor speeds, which greatly extends the service life of the wiper blades, mechanical seal and drive bearing.

No Bottom Steady Bearing

Unlike a typical fixed clearance evaporator design, the WFE rotor is supported entirely from the top drive and bearing assembly, all mounted to the WFE top cover and main shell flange. This is accomplished by means of our robust overhung design. With no bottom steady bearing, no flux oil is required, which is critical when non-volatiles are the product.

Low Horsepower Requirements

The low rotor speed significantly reduces horsepower requirements. This provides a significant savings in use, especially when compared to the same size fixed clearance evaporator.

Expandable WFE Sizes

For some models, additional thermal sections can be installed above the original thermal section at your plant site to provide increased capacity for existing WFEs. Easy Rotor Removal Any size WFE rotor can be removed and reinstalled in 30 minutes or less. Simply disconnect the motor leads, feed line, and bolts, then lift the rotor out of the shell as one complete assembly. This allows for quick, easy, inspection, maintenance, and cleaning.

Internal Condenser

Our design with no bottom steady bearing allows for the installation of an internal condenser. WFEs with internal condensers minimize pressure drop compared to external condensers, allowing for high-vacuum operation. The high vacuum, and the proximity of the condenser surface area to the heated wall, provides better separations and ensures complete condensation and sub-cooling.

Efficient Entrainment Separators

Specially designed, full-length entrainment separators for standard and high-vacuum operation effectively remove entrained droplets from the vapor stream and improve the purity of the distillate product.

High-Vacuum Operation

The high-vacuum design of our WFE can operate with vacuums as low as one micron (.001 torr). Operating at deep vacuum lowers operating temperatures and prevents thermal degradation.

Bottoms Outlet

For viscous materials with high melting points, the WFE bottom head can be heated, and extruder blades can be utilized to mechanically aid in discharging heavy material.

Low Maintenance

Depending on the application, we recommend only one shutdown per year for 1-2 days for inspection and maintenance. Mechanical seals typically last for many years. There is no bottom bearing and thus no costly maintenance.

Our Drives

Our unique WFE drive assembly enables our customers to easily access the mechanical seal for replacement without having to remove the complete rotor assembly, minimizing down time and extra costs associated with overhead cranes.

FAQ Wiped Film Evaporators (WFE)

A WFE is a speciality thin film evaporator for difficult separations. Internal rotating components wipe the process material into thin film for improved heat transfer.

The WFE is used in difficult separate applications, including HIGH VISCOSITY (for example polymers) and HEAT SENSITIVE PRODUCTS (for example nutraceuticals) and HIGH FOULING (for example used motor oil re-refining) and HIGH BOILING POINT PRODUCTS (for example any high molecular weight material where operation at very high vacuum is necessary to reduce temperature).

Typically, the WFE is fabricated with stainless steel, duplex stainless steels or high nickel alloys, but is also available in glass and glass-lined steel construction.

Watch our WFE Operation Video to see the components of the WFE and how it operates.

The WFE was invented in Rochester, NY, and GMM Pfaudler acquired the rights in the early 1950's and has been providing WFEs and complete WFE Systems globally since then.