Absorption Systems

Systems

Overview

Absorption is the intake of gases in a washing liquid through physical solving (physisorption) or reversible chemical reaction (chemisorption).

A wide range of specific solutions can be applied as customized and process specific units.

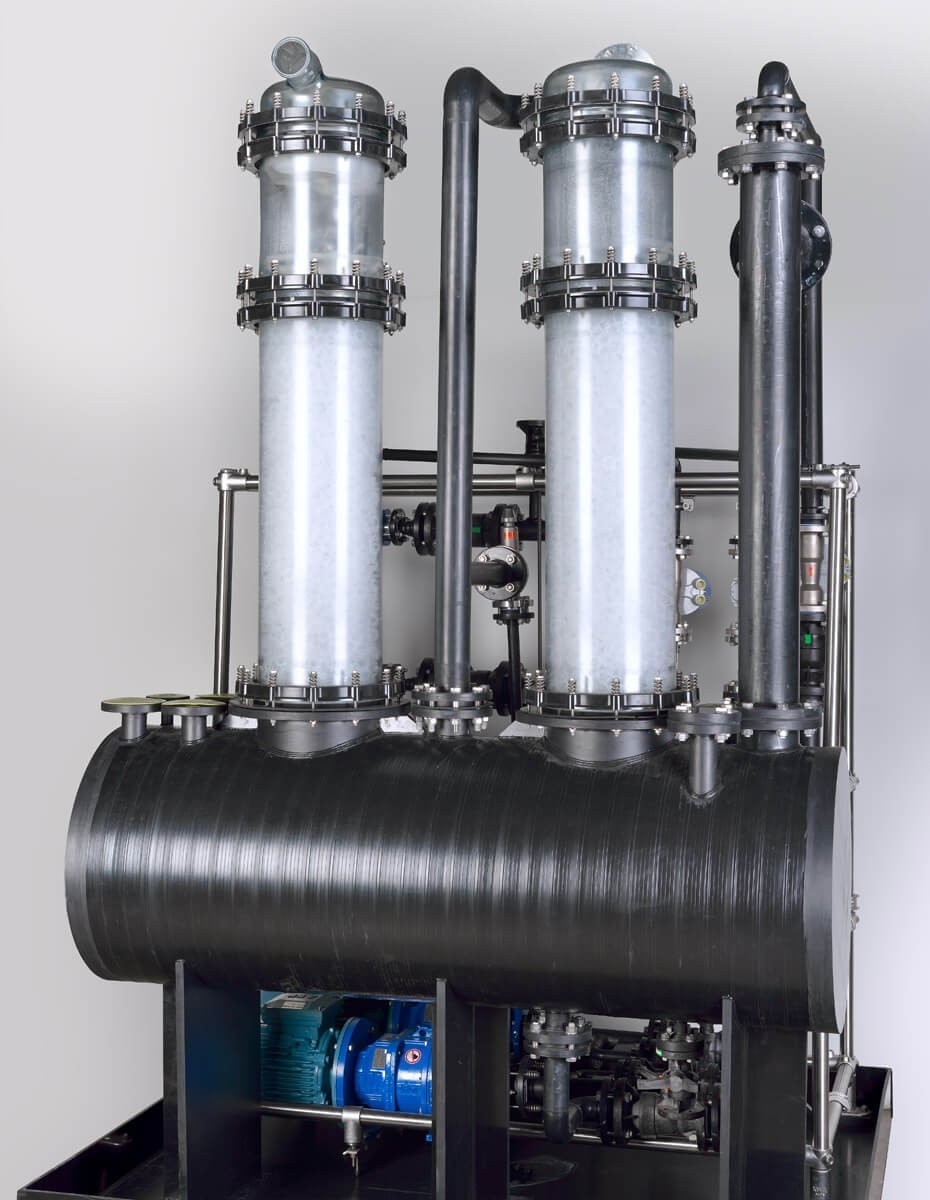

GMM Pfaudler Systems designs, manufactures, and commissions complete process solutions for NOx, HCl, and waste gas absorption systems.

In addition to creating safe, reliable, efficient, environmentally safe, and profitable solutions, GMM Pfaudler also provides process engineering support to its technologies and service department.

Pfaudler Absorption Systems

NOx Absorption technology recovering nitric acid from vent streams. Nitrous gases are oxidized using atmospheric air and absorbed in process water. For most applications, the effluent gases comply with all environmental standards without additional treatment. Customized solutions can be provided.

Pfaudler Systems offers solutions from atmospheric pressure, and from low pressure absorption to medium pressure absorption.

With HCl absorption technology, hydrochloric acids are recovered from vent streams. HCl is absorbed in process water forming hydrochloric acid. Depending on the gas composition and the required product concentration, adiabatic or isothermal absorption will be applied. For most applications, the effluent gas complies with all environmental standards without additional treatment. Customized solutions can be provided.

If the compounds in the waste gas need only be removed, and recovering valuable products from compounds is not reasonable, Pfaudler’s Engineered Systems offer customized scrubber systems under applicable environmental standards.

The use of high-quality materials allows us to design individual units for the various requirements of laboratories and for various production processes. For example, Pfaudler can provide ATEX designs, as well as vessels in different sizes and materials, like Borosilicate glass 3.3, or glass-lined with glass covers. Many other customizations and adjustments are available.

Standards & Directives

Standards and directives are of great importance for manufacturers of machines and safety components. Pfaudler is able to share its knowledge with its clients by designing equipment and components that meet the following directives:

- EC Machinery Directive 2006/42/EC

- PED 2014/68/EU

- AD 2000 set of rules

- TA-Luft

- ATEX 2014/34/EU

- DIN/ISO 3585

- ASME

Other directives and standards can be considered after assessment, according to the specific needs of Pfaudler’s clients.

Main Technical Characteristics

- Corrosion-resistant expertise

- Customer & process specific design

- High-efficiency design

- Solutions providing the highest environmental standards, using the best available techniques (BAT)

- Selected certified suppliers and a long history of tried and tested products (pumps, sensors, valves etc.), guarantee a long-term replacement parts supply.

Scrubber Systems

In the event that compounds in the waste gas must only be removed and recovering valuable products from the compounds is not possible, Pfaudler offers customized scrubber systems, in accordance with applicable environmental standards.

Depending on the substances to be removed, caustic scrubber, reductive scrubbers, or oxidative scrubbers are applied. Pfaudler can provide a customized solution tailored to your individual needs.