Sulfuric Acid Concentration and recovery.

23 January 2017

Sulfuric Acid Concentration and recovery.

Sulfuric acid is a highly corrosive mineral acid with the molecular formula H2SO4. Sulfuric acid is the most widely produced/consumed chemical at over 200 million tonnes per year. Chemical plant waste acid streams are often simply neutralized prior to transfer to waste water treatment facilities. Rising operating costs in difficult economical times creates the need to recover the sulfuric acid for further use. Stricter environmental regulations globally also mandate recovery of sulfuric acid rather than waste treatment.

Pfaudler Technologies

Pfaudler‘s corrosion-resistant materials such as glass-lined steel (Glasteel®), our Edlon fluoropolymer-lined steel technologies and our reactive metals (Zirconium and Tantalum) technologies are required for the safe containment and processing of sulfuric acid. Pfaudler has the largest number of customer installations of glass-lined and fluoropolymer-lined equipment for corrosive applications in the Chemicals Industry. Pfaudler invented Glasteel® in 1884, pioneered the use of fluoropolymer technologies for process applications with our Edlon division in 1964 and were the first to fabricate process equipment from Zirconium in 1938 in Tantalum in 1946.

Pfaudler Solutions

Pfaudler’s Engineered Solutions Group designs, fabricates and commissions complete process systems with Pfaudler’s Sulfuric Acid Concentration Technology at the core. At the heart of this Engineered Solutions Group are chemical engineers with vast experience and expertise in all chemical operations, including: Evaporation, Distillation, Mass Transfer, Reaction, Mixing, Heat Transfer, Filtration, Fluid Flow, Drying, and more.

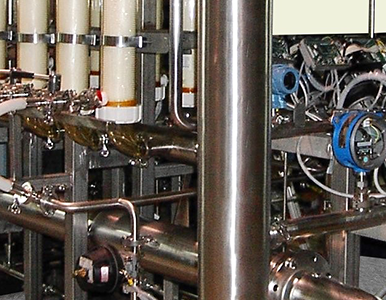

We have designs for concentration up to 96%wt. and capacities up to 1200 MTPD. These complete systems include the acid concentrator/evaporator plus all ancillary equipment, instrumentation and piping completely assembled on structural steel modules or field fabricated. Each system is designed specifically for our clients’ process. The layout is custom designed to ensure proper system functionality and to ensure all equipment, instruments and valves are arranged for ease of operation and maintenance. This single source responsibility ensures the design of every component is integrated into a complete system design to ensure proper system performance.

Benefits

• Efficient compact layouts - to save plant real estate and reduce hold-up volumes.

• Multi-effect design – for operating cost reduction

• Heat recovery options - for energy conservation

• Pilot Test Facility – to confirm performance and collect scale-up data

• Ancillary systems design – organics removal, NOx scrubbers and utility systems

• Field services – installation, maintenance, spare parts

Contact Pfaudler today to learn more.