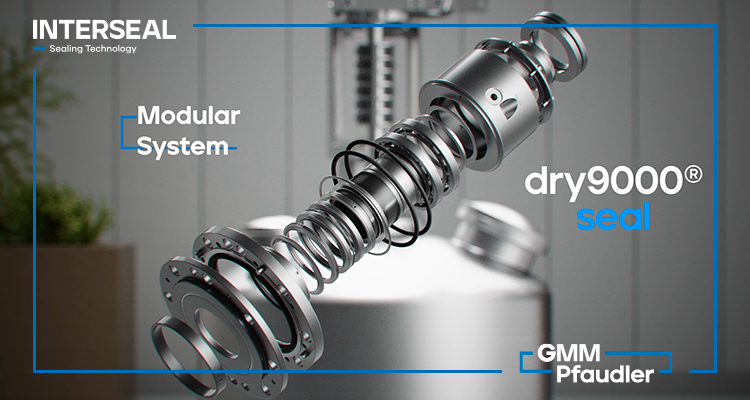

dry9000® state-of-the-art technology

Interseal Sealing Technology

Technologies

dry9000® Follows Every Movement

No matter whether motion is abrupt, vibrating, or tumbling, shaft deflections that act as forces in production processes lead to gaps between sealing surfaces when conventional seals are used. This results in wear followed by leakage through seals.

The dry9000® follows every axial and radial movement of the shaft, thereby eliminating any movement of the sealing components, which results in no gaps in critical sealing surfaces and a leak-free sealing system. This proves the superiority of our shaft lip seal.

Conclusion: Since there is no relative movement of the dry9000® sealing components, there are no gaps between the sealing surfaces and, therefore, no medium can penetrate the sealing system.

No other system on the market offers this technical capability.

Dry Running

Our dry9000® offers a standardized solution for: agitators, mixers, thin film evaporators, screw conveyors, Nutsche filters, and filter dryers.