dry9000® for Custom-sized Solutions

Interseal Sealing Technology

Technologies

For custom-sized Solutions

dry9000®

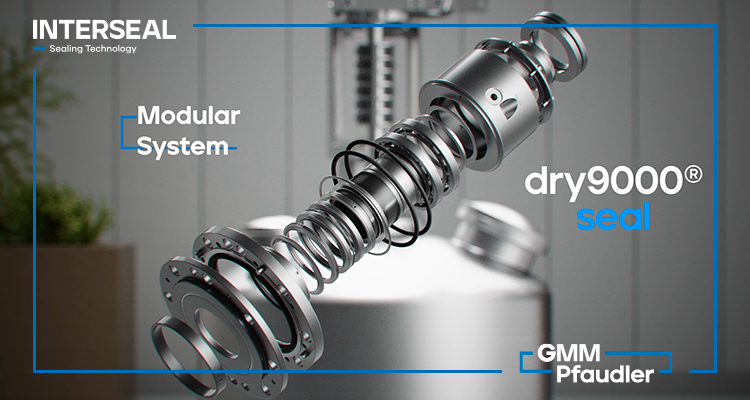

Modular Concept dry9000: one system - unlimited options

Productivity has many expressions but quite totally different requirements.

Pfaudler’s motto is “yes we can!” Starting with its standard solutions, available within 24 hours, or customized standard solutions and custom-made special products, the interseal dry9000® is available in various formats in a modular concept. This ensures that every production line can benefit from all the advantages of Pfaudler’s seals. The interseal dry9000® can easily be built into any machine, regardless of the manufacturer.

Available within 24 hours: Pfaudler’s standard solution

For agitators and mixers manufactured in accordance with DIN standards, with 40-to-140 mm shaft diameters, the dry9000® is available from stock.

Develop your advantage: Pfaudler’s custom-made special seal for your environment

Does your production occur in an exceptional environment?

Pfaudler is ready to take on the challenge. Upon request, an adapted variation of the dry9000 that meets your single needs can be developed.

dry9000® for Horizontal Mixers

Horizontal mixer seal – dry9000® extend

Axial-radial-flexible seal with compensation, using an expansion disc or metal bellows for machines with larger shaft expansions.

The seal is available as a plug & play cartridge, and will be adjusted to the connection set-up of the machine.

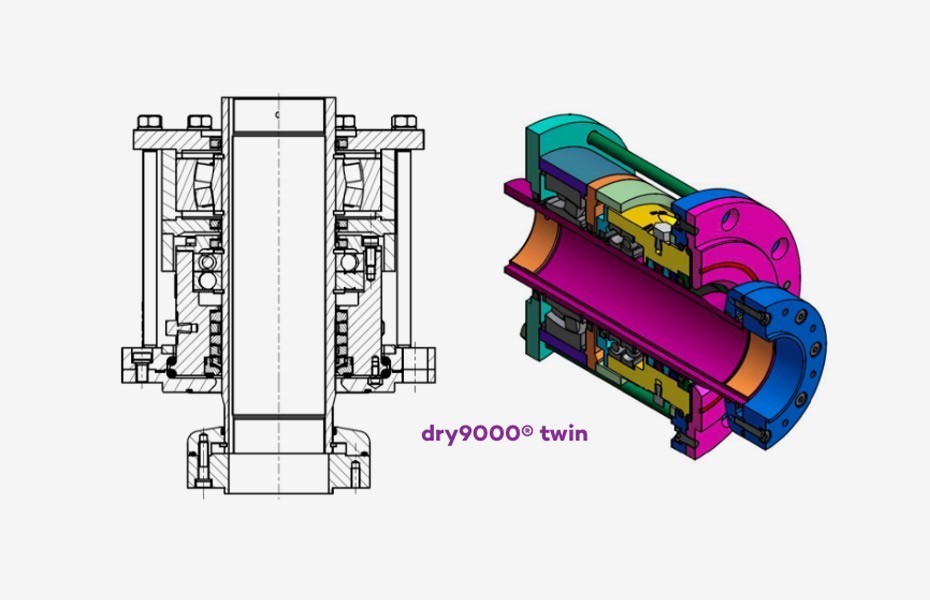

dry9000® for Filter Dryers

MAVAZWAG Agitated Nutsche Filters and Filter Dryers are versatile units for deep bed, solid-liquid separation using a filter screen. These are particularly effective in the pharmaceutical and chemical industries where filtration and cake washing are required.

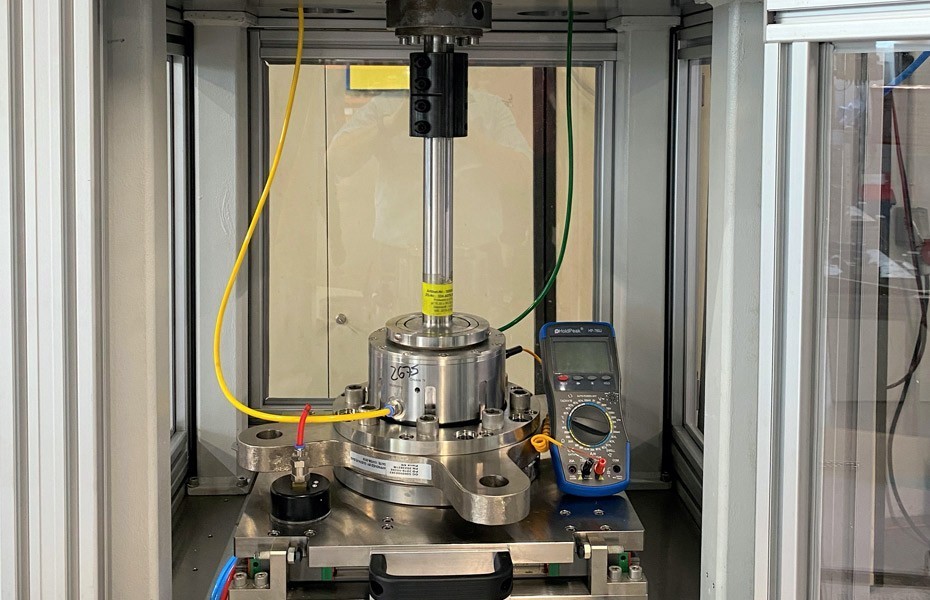

Pfaudler interseal dry9000® twin N+ sealing technology is installed on MAVAZWAG equipment. The combination and full compatibility of this technology guarantees high quality and performance equipment, in line with the most complex clients’ needs.

Furthermore, Pfaudler interseal can customize the dry9000® in order to meet your filter dryer specific requirements.

dry9000® Innovative Movable Stripper

Protection concept for dynamic sealing systems in demanding procedure environments

The production of solid and drying processes demands higher requirements for dynamic sealing technology. Products (like solid, crystalline parts), are usually right close to sealing parts, or can even touch them. A seeping product can damage the sealing elements and lead to a reduction in lifespan, needless production losses, and increased production costs.

For the pharmaceutical production, Pfaudler was faced with an additional challenge with regard to a GMP - cleanness requirement – design for sealing solutions. For these applications, dead spaces must be reduced to a minimum.

A perfect design is where the product does not get stuck in difficult areas that cannot be cleaned. Abrupt, vibrating, or lurching movements of the mixer shaft are the common causes of the main dynamic seal problems.

The perfect solution is a design without a relative movement of the actual sealing components. That means no stress inside the sealing system – no axial or radial movements that could cause problems.

Developing innovative solutions

Pfaudler succeeded in developing a design that could fulfil all needs in the pharmaceutical industries’ processes.

The main feature is the so-called “metallic lip” shape that works like a shield in front of the sealing lip.

The product no longer comes into contact with the lip and, therefore, cannot damage it.

Of course, this high-end solution can follow the shaft movement, meaning no gap is created, even if the agitator shaft vibrates. A GMP design and CIP possibilities are just another unique result of this innovation.

One great option is that the user can add more nitrogen in between this scrapper and the seal. This further increases the lifespan and reduce the TCO.