Normag - Lab & Process Glass

About Normag

NORMAG is a high-quality brand of glassware for the chemical and pharmaceutical industry and research.

Thanks to our experience and the skills of the team, we are able to design, engineer and manufacture plants for laboratory and production.

Company history

The company dates back to 1887, when it was founded as a glass-blowing company in Germany before rapidly developing into a high-quality supplier of laboratory glassware in the growing chemical-pharmaceutical research and industry.

Thanks to our expertise in glass-blowing, NORMAG (formerly Normag Labor- und Prozesstechnik and today PFAUDLER NORMAG Systems) was chosen in the 1950s and ‘60s as a partner in the Research and Development department of the chemical and pharmaceutical industries, with the aim of advancing and expanding laboratory components which provide reliable experimental data. Based on the results achieved with this cooperation (the word cooperation is a noun. You can also say joint project), the NORMAG brand developed a unique and highly-qualitative laboratory component program.

In the 1980s and ‘90s, the multitude of customer requirements included not only components, but also complete apparatus and units. This presented the ideal next step for NORMAG—the set-up of glass apparatus and units based not only on high quality, but also process-specific and well-specified components.

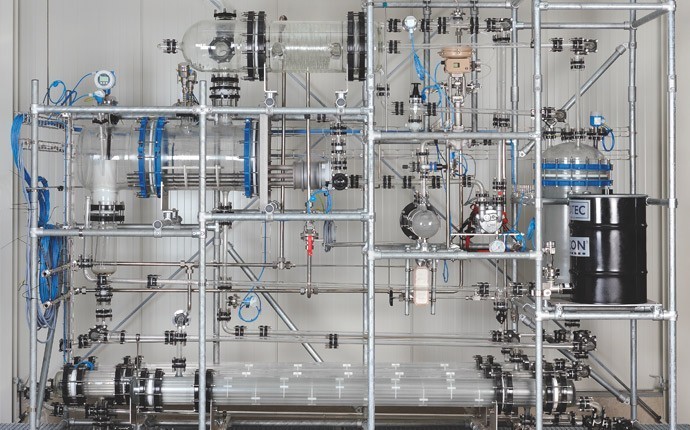

The range of apparatus and units grew to include not only glass units, but also process-specific combinations of glass with other highly corrosion-resistant materials and stainless steels.

Since September 2017, PFAUDLER NORMAG Systems has been a part of the GMM Pfaudler Group. The integration with components and apparatuses in corrosion-resistant materials—such as enamel, fluoropolymers and alloys—paired with cutting-edge technologies for agitated vessels, separation as filtration as well as drying, ensures further opportunities in the chemical process market.

Normag today

PFAUDLER NORMAG SYSTEMS currently supplies components to complete units in glass and other materials, from the laboratory to production scale.

The product portfolio includes individual components in borosilicate glass 3.3 or other highly corrosion resistant materials plus systems and apparatuses, such as evaporators, columns, condensers, filters, extractors and settlers. There are also process units, including reaction and mixing units, units for distillation, rectification, evaporation, filtration, stripping and absorption; not to mention fully-engineered production systems for acid and solvent recovery or any other chemical process.