New Pfaudler Laboratory Test Facility in Waghäusel, Germany

24 November 2019

New Pfaudler Laboratory Test Facility in Waghäusel, Germany

Process development plays a major role in developing solutions for the critical needs of our clients.

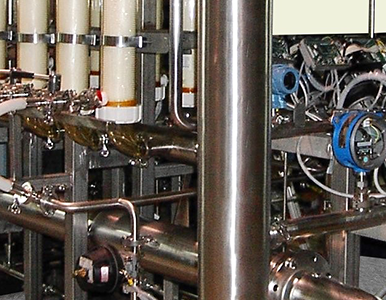

The new Pfaudler laboratory test facility in Waghäusel offers a wide variety of testing possibilities, which guarantee process performance.

Main equipment is manufactured by NORMAG from high corrosion resistant borosilicate glass enabling visual process investigation.

Several types of evaporators like Forced Circulation Evaporator, Falling Film Evaporator, Thin Film Evaporator etc. are installed and can be operated in atmospheric and vacuum conditions.

Random packed and tray columns are available for rectification and distillation tests.

Customized testing for client’s processing optimization with organic and inorganic substances can be performed and Pfaudler Normag Systems will be in a position to grant the relevant process guarantees.

In Pfaudler Normag Systems special area of expertise, the treatment and concentration of spent acids, thermal-chemical treatment and concentration tests with original and synthetic spent acids can be executed. This includes process optimization regarding product quality and/or emissions as well as consumption of chemicals for treatment. This applies to most of the inorganic acids as well as organic acids.

Direct scale-up of the results is possible. No pilot plant is required in most applications.

This gives our clients a cost-effective option to verify and determine the relevant requested qualities.

Main Features of Product

- Forced Circulation Evaporator

- Falling Film Evaporator

- Thin Film Evaporator TVO

- Atmospheric and vacuum operation

- Thermal-chemical treatment and concentration

- Random packed and tray columns

Key of Success

- Possibility to test original spent acids

- Process optimization without pilot plant

- Process design optimization

- Tailor-made process solutions

Benefits for the customer

- Concentration by evaporation under atmospheric or vacuum conditions

- Concentration by rectification under atmospheric or vacuum conditions

- Process optimization with regard to product quality and/or emissions

- Selection of suitable chemical agents

- Development of new processes

- Tailor-made process design

- No pilot plat necessary in most applications

Contact Pfaudler today to learn more: Hansjuergen.Winterbauer@pfaudler.com