Mixion

Mixion - Mixing Technology

Overview

Mixion focuses on engineering solutions and sustained innovations with superior industrial mixing solutions & technologies. Mixion, derived from mix and ion, reflects our competency in the core science of mixing and our ability to demonstrate mixing simulations.

Our competence in industrial mixing solutions comes from our experience of over 35 years. Our collaboration with renowned academia at the Institute of Chemical Technology Mumbai (India) has helped us innovate and improve the mixing performance of our designs.

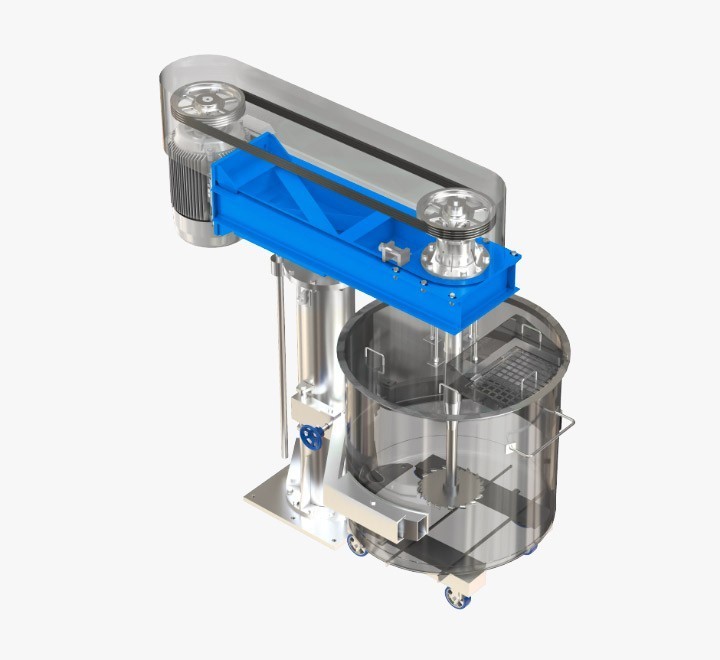

Under Mixion, we offer our customers agitators & mixing solutions that help improve efficiencies, yields, and reduce costs. We offer full-line expertise in mixing which includes designing, simulating, engineering, and manufacturing industrial mixers and agitators, reactors, and other allied mixing equipment.

20.000+

INSTALLATIONS WORLDWIDE

500+

CUSTOMERS GLOBALLY

From lab-scale to large sized efficient mixing solutions, our capabilities include:

- Special offerings like motors (FLP, Ex’d’, Ex’e’, Ex’n’), gearboxes (bevel, helical, planetary), sealing arrangements (API Plan 52, 53, 54) including ATEX certification & CE marking

- Expertise to offer unique material of construction including Titanium, Hastelloy, Monel and Inconel

- Sanitary design mixing solutions for sterile applications with surface finish up to 420 grit

- Installation of over 100 large agitators with 30-meter-long shaft and 6-meter impeller sweep diameter

- Offering special coatings or linings like Rubber, PTFE, Halar, FRP, PVDF

- In-house designing and manufacturing of agitators and special team assigned for their after-sales services like commissioning, supervision, and erection activities

Visualization of Mixing Performance

With Computational Fluid Dynamics (CFD) it is possible to gain insight into the overall mixing performance of the process equipment and obtain multiple views, based on critical parameters. Many process-related questions can be analyzed in advance before any manufacturing step of equipment is started. We have been successfully using CFD related to mixing/process technology and heat transfer, and have practical experience in verifying mixing systems and doing feasibility studies.