Minerals & Metals

Mixion - Mixing Technology

Agitators for Mining Industry

Slurry Agitators, also known as agitators for mining industry, find applications in almost all the Mineral & Metal industries like Iron ore Beneficiation plants, Alumina, Zinc, Lead, Copper, Silver, Coal ash, Uranium, Phosphate, FGD, lime, etc. The mixers for mining industry are typically top entry agitators used in liquid & solid mixing application. The primary objective of liquid – solid mixing is to create and maintain a slurry and/or to promote and enhance the rate of mass transfer between the solid and liquid phase.

Alumina Industry

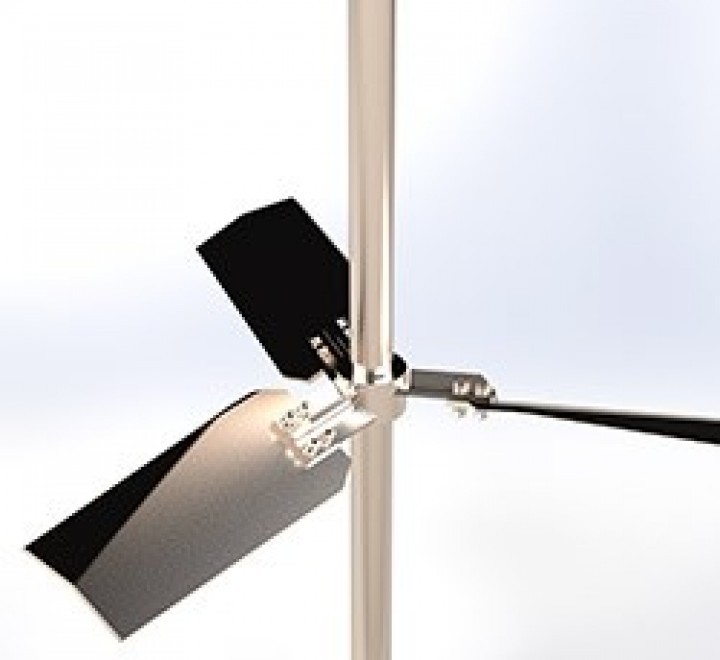

Pre-desilication (PDS) application in Alumina industry is the removal of silica from the ore by addition of caustic in which the alumina dissolves leaving behind red mud or silica as waste for removal. Precipitation tanks (PPT) application involves precipitation of ore. In both PDS & PPT applications the solid concentration levels can vary from 20% to 55%. These require axial flow-based impellers as the agitators used in this application are for uniform suspension. The impeller technology used in PDS agitators is axial flow-based - hydrofoil impeller.

Each agitator may have multiple impeller stages based on the tank height. These agitators are low-speed agitators below 50 rpm. The rpm selection is done carefully to ensure that the optimum tip speeds are achieved yet delivering the required flow to the process. The tank sizes are big ranging from 10 m3 to 5000 m3 with solid concentration levels up to 65%. Agitators in these applications are included for off-bottom suspension, uniform suspension, re-suspension of settled solids, incorporation of floating solids, dissolution, dispersion of solid aggregates and as such has designs based on the mechanical loads, fluid forces considering draw off conditions, settling velocities, start-up in settled solid conditions, etc.

Our top entry agitators with hydrofoil impeller and specially selected gearbox designs are most suited for this application. In addition to PPT and PDS, our agitators are used for Hydrate Slurry, Digestion Tanks, Spent Liquor, Filtration, Mud Wash, Leaching and Crystallization tanks. The agitators can be offered for batch or semi-batch of continuous stirred tank operations. We have over 50 installations for such applications.

Based on the application requirement, rubber lining for wetted parts can be provided. Bottom supports in cases where necessary are included. Drive arrangements with standard or special motors, gearbox types – inline helical, bevel helical, parallel helical are our offering capabilities. We take pride to highlight our installations as huge as a 30-meter-long shaft made from 500 NB pipe with 4 stages of impellers, each impeller of a 6-meter diameter.

Iron Ore Industry

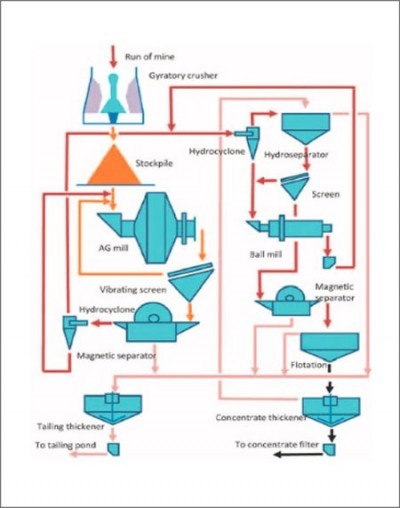

In the case of low-grade mines or where the product iron grade needs further improvement, secondary crushing is replaced by the beneficiation process. The beneficiation process mainly comprises of the subprocess of grinding, separating, and dewatering.

The basis for agitator design for the concentrated iron ore slurry tank or tailing slurry tank is for off – bottom suspension and an agitator with single impeller design is more sufficient to generate the flow to achieve the suspension. Narrow bladed hydrofoil is the commonly used impeller which can produce higher flow for given lower power input.