Lab Fast Pro Filter Reactor

- Universal support frame, that accommodates vessels from 1l to 10l

- Temperature range: -90ºC to +200ºC

- Three sizes of the main flange (DN100, DN150, DN200) available to work with different sizes of the vessels

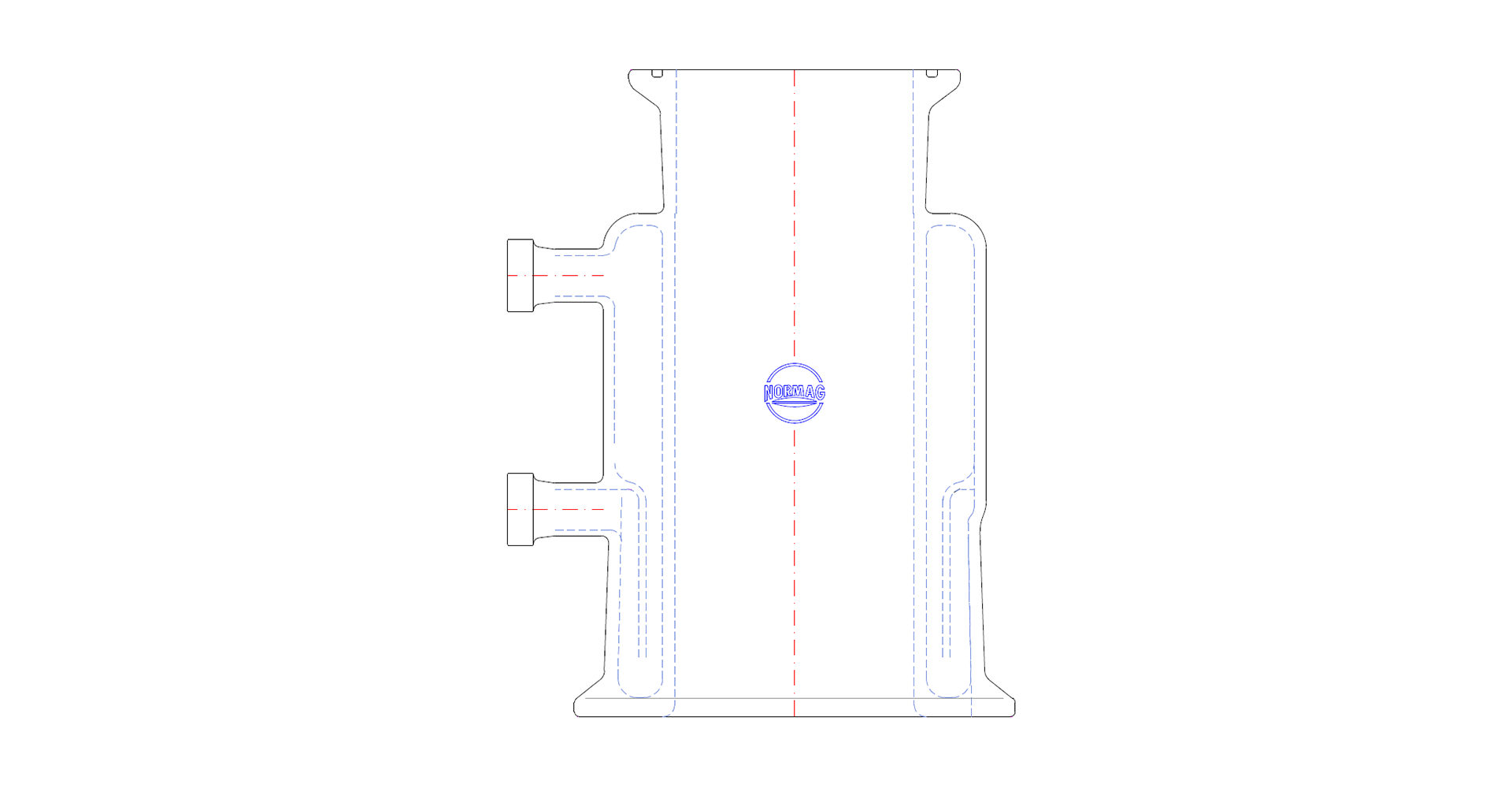

- Full-jacketed design with deflector guarantees efficient heating and cooling right from the bottom up to the top

- Set of different plug&play packs (pH-measurement, reflux, gas purge etc) to meet your process requirements

Overview

The Lab Fast Pro Filter-reactor was designed by collective efforts of chemists and engineers for chemists. It allows to work with vessels of different sizes by changing the glassware in mere minutes, not hours. A unique frame design allows you to easily operate the filter.

This concept will not only save you time, but also money. Through the universal design and the usage of standard joints allows the usage of any thermostats, pumps and glassware from any manufacturer, thus giving unmatched flexibility. If you need even more versatility, you can always ask for additional customization, we are ready to help!

Typical applications for the filter reactor are solid phase synthesis (peptide synthesis) and extraction from solids (e.g. presious metals out of ore or organic compounds out of plant leaves).

Why you should buy this system from NORMAG

UNIVERSAL SUPPORT FRAME

- Vessels from 1l to 10l on one support bench-top frame

- Fits reactors, filters, filter-reactors

- PE drip tray

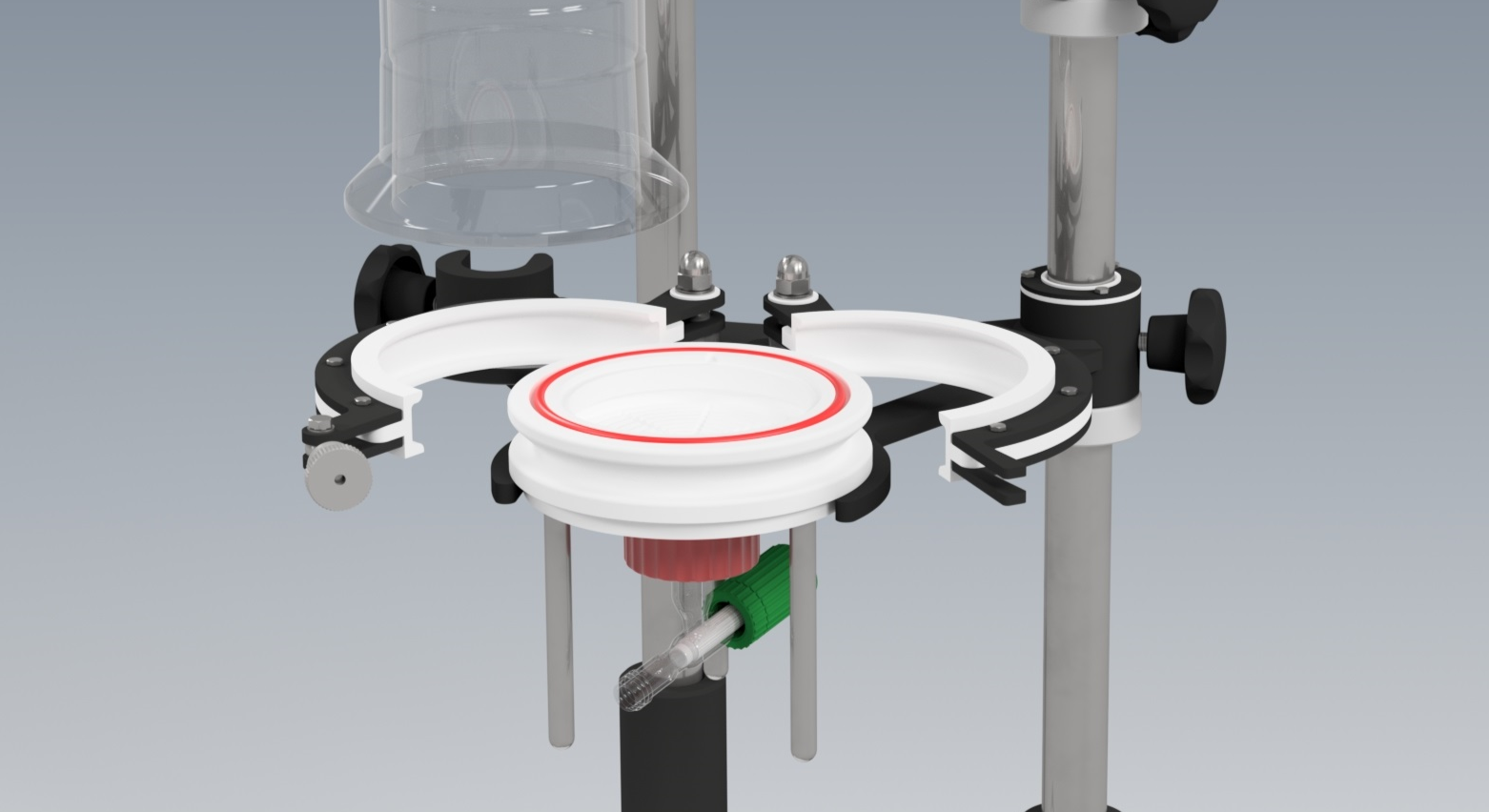

UNIQUE CLAMP

- Holds vessel even when lid clamp is opened

- No tools or additional accessories are required to mount the vessel or to regulate tightness of the seal.

VESSELS WITH MAXIMUM FILTRATION AREA

-

Neck of the vessel depends on the size.

- DN100 – 1l (0.008m2)

- DN150 – 3l, 5l (0.017m2)

- DN200 – 10l (0.030m2)

- Non jacketed and full-jacketed design depending on your process requirements

- Integrated deflector for the jacket inlet port to ensure even heating or cooling all along the vessel’s wall

UNIQUE TOOL FREE CLAMPING MECHANISM FOR THE FILTER BOTTOM

- Full chemical resistance – only glass and PTFE is in contact with product

- Integrated feet allows you to place the bottom part anywhere without being afraid of damaging the glass drain valve

- Tilting mechanism for easy discharge of the product.

- Accommodates any filter materials with thickness up to 1mm

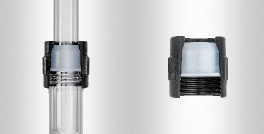

UNIQUE STIRRER GUIDE

- No PTFE flaking thanks to PEEK-to-Glass sealing

- Working 24/7 from a slight overpressure down to 7mbars

- Only PTFE, glass and PEEK are exposed to vapors/media, which guarantees perfect chemical resistance

STIRRER GUIDE QUICK COUPLING

- No more worries about possible stress in the center neck even when drive is not positioned 100% concentrically

- No tools required to engage stirrer coupling and stirrer guide

- No need to precisely center the stirrer drive thanks to a unique design

- Fits any chuck with chucking diameter of 8mm or bigger

- Continuous operation up to 500 rpm or even 800rpm for a short period of time

OVERHEAD STIRRER HOLDER ALLOWS TO EASILY POSITION THE OVERHEAD STIRRER

- Fits any overhead stirrer that you can find on the market with 13mm or 16mm rod (IKA, Heidolph etc) or even powerful ones with two rods (CAT)

- Overhead stirrer chuck will always stay vertical thanks to extended support bed

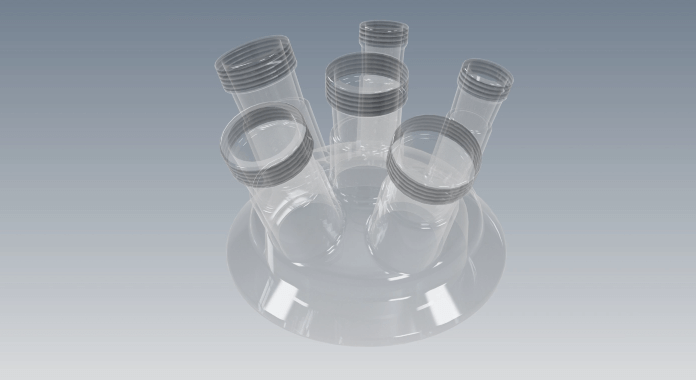

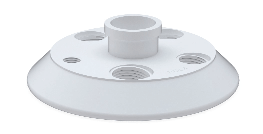

UNIVERSAL LID OF THREE SIZES (DN100, DN150 and DN200) WITH 1 CENTRAL AND 5 PERIPHERICAL NECKS

- allows to install not just stirrer guide and condenser, but also different sensors, dosing funnels for liquids and solids and many more

- Security joints (SJ) for a reliable glassware fixation without additional clamps

- Standard B-type joints 4xSJ29/32 and 2xSJ19/26 allow to use anyglassware from 3rd-party manufacturers

Additional modules and accessories

1.

Set of drain and ventilation valves with clamps for easy draining of HTF (oil), when replacing one vessel with another

2.

Distillation module. Includes reflux divider with receiving flask of your choice and set of PTFE tubes and fittings. Allows to perform distillations and concentrate your reaction mixtures

3.

Liquid dosing module. Includes a chemical resistant membrane pump with a dosing speed starting from of 0.03ml/min and all necessary clamps to fix it on the frame and fittings to connect it to the reactor

4.

pH-module. Includes pH-meter with 425mm 3in1 pH-sensor and a PTFE adapter to fit any vessel size

5.

Gas distribution set. Includes Gas inlet tube, gas frit and adapter to mount on the reactor’s lid

6.

Range of different stirrer shafts with additional rotors for better mixing of even high viscos media

7.

Solid dosing funnels with volumes from 50ml to 1000ml with integrated cooler at the bottom to prevent vapors going from the reactor into the funnel

8.

Liquid dosing with jacketed and non jacketed funnels with volumes from 50ml to 1000ml

9.

Customizable PTFE lids to work with heavy equipment like homogenizers or ultrasonic generators.

10.

Fittings for an easy and tight connection of bottom drain valve to other units like receiver, filter, another reactor etc

11.

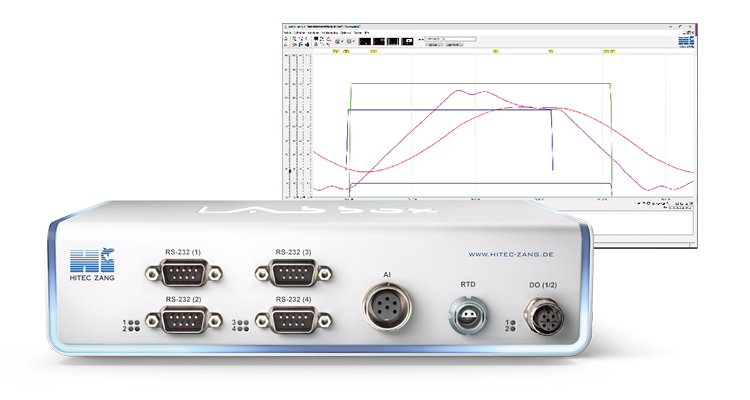

Software and hardware for process automation

NORMAG Lab & Process Glass Custom Solutions

You need customizations that are tailored to your exact needs.

Contact us, we will find the right solution for you.

The Normag experts are there for you, listen to you, develop with you and for you the customized solution that gives you all the freedom.

Do you have an inquiry?

Contact the GMM Pfaudler Group via the dedicated form or consult the list of locations worldwide. We will provide a single point of contact through our sales, service and internal support groups.

How can we help you?

Our team is at your disposal to facilitate your steps and offer you personalized support.