Distillation and Evaporation Systems

Normag - Lab & Process Glass

Technologies

Overview

Removing or separating liquids is a very common application in lab, pilot and industrial scale. There are different types of equipment, that can help you with this

- Thin Film Evaporator

- Continuous Thin Film Evaporator

- Short Path Evaporator

- Continuous Short Path Evaporator

- Falling Film Evaporator

- Batch Distillation

- Azeotrope Distillation

- Spinning Band Column

- Continuous Distillation

- Continuous Distillation with Falling Film Evaporator

- Continuous Distillation with Thin Film Evaporator

- Continuous distillation with circulation evaporator

Each one has its own advantages and field of application

Evaporating in a Thin Film

Thin Film Evaporator (TFE) is used to remove low boiling components (usually solvents) from the solutions of thermolabile compounds that cannot be processed in a rotary evaporator. The acting principle is very simple: a solution of the target compound is fed through the top of the main heat exchanger and distributed evenly along the walls by means of the rotating scrappers, creating a very thin film. The Solution flows down along the walls thanks to the gravity while a light solvent evaporates. As the interval when the solution is in contact with heated walls of heat exchanger is very short and solvent takes away all the heat, compound doesn’t decompose. The concentrated solution flows down to the receiving vessel and later can by dried e.g. in a freeze dryer. Solvent’s vapors go to the condenser, where they condensate and are collected in another receiver. Working pressure in such units can reach down to 0.1 mbar and maximum temperature can be up to +300oC, depending on the materials in use.

Short Path Evaporator (SPE) is similar thin film evaporator. However, it is intended for separation of two high boiling liquid compounds. Vapors of a lower boiling (but still a high boiling one) compound evaporates from the inner surface of main heat exchanger but run over a very short path to the condenser, which is located in the middle of the main heat exchanger, and condensate on it. Thus, both compounds can be collected in a separate vessel, thanks to the unique design of the SPE. Working pressure in such units can reach down to 0.001mbar and maximum temperature can be at to +300oC

Falling Film Evaporator also provides evaporation of a thin film layer, but this time the initial solution is fed from the bottom of the unit by means of a special pump. The Solution is risen to the top of the heat exchanger and flows down by means of gravity along its walls. There are no rotating scrappers in such systems which improves the robustness.

All three types of the systems can be upgraded with liquid dosing and discharge pumps for a continuous operation. And all three systems can work with viscous substances, because the substances can be easily preheated.

It is important to mention, that these units are intended for a separation of compounds, that have a boiling temperature difference of at least 20K at desired vacuum. Smaller difference will result in a lower separation degree.

Rectification (Fractionating columns)

You have to go for rectification, when you have to separate complex mixture and/or mixtures of compounds with similar boiling points. Main advantage of this method is a possibility to separate components with a very intimate boiling points like e.g. structural isomers.

The key to the method is constant counterflow heat/mass exchange between vapors and condensate. Process is held in columns with regular or irregular (raschig rings etc.) packing. Thanks to the packing the contact area of vapors and condensate is increased by hundreds and thousands of times which leads to a much higher separation rate.

There is also another system similar to a classical rectification column which is called the Spinning Band Column. This system has a screw-mechanism which constantly rotates at high speed. Screw-mechanism forces vapors into contact with the condensate on the surface of the column. This contact takes place in a very thin layer and refreshes hundreds of times per second. This allows to obtain a very high separation rate even in a relatively short column.

Both packed and spinning band columns can be equipped with dosing and discharging pumps, which allows to have a continuous system, operating 24/7.

Columns can be constructionally combined with TFE, having them as the first stage which increases the purity of the target product.

Range of Products

Spinning band column

Batch distillation

Azeotrope distillation

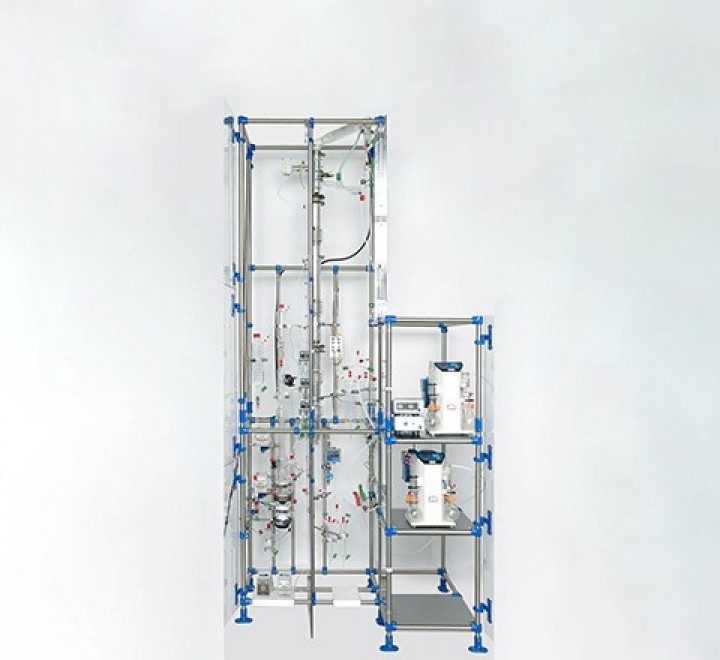

Continuous distillation

Continuous distillation with falling film evaporator

Continuous distillation with thin film evaporator

Continuous distillation with circulation evaporator