Agitation Tasks

Pfaudler - Glass-Lined & Alloy Systems

Technologies

Mixing Tasks

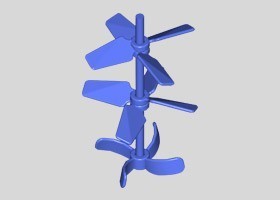

There are multiple specific mixing tasks in glass-lined reactors. Several tasks can appear simultaneously. This occurs in the process industry. Optimized results (product quality, process time, productivity, and so on) are obtained in the configuration of the most suitable agitator, assuring the task is carried out in the shortest time, at the lowest cost.

Pfaudler’s range of glass-lined turbines offers the best answer to fulfil these requirements:

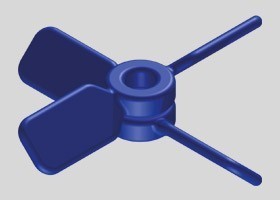

MFI: Multiple Flyer Impeller

FDT: Foam Destruction Turbine

Homogenization

Definition: Generation of a uniform phase of several mutually soluble liquids. Compensation of temperature and concentration differences. Recommended Pfaudler turbines:

Low – medium viscosity: CBT, TBF, MSG, RBT

Medium – high viscosities: CBT, MXT, MSG

Suspension

Definition: Whirling up and suspending a solid in a liquid for the purpose of dissolving or performing chemical reactions Recommended Pfaudler turbines:

Low – medium viscosity: TBF, CBR, MXT, MSG

Medium – high viscosity: MXT, MSG

Crystallization

Definition: Generating crystals e.g. by cooling down a liquid.

Recommended Pfaudler turbines:

Low – medium viscosity: TBF, MXT, MSG, RBT

Medium – high viscosity: TBF, MXT, MSG

Heat Transfer

Definition: Heating/cooling media by supplying/removing reaction heat.

Recommended Pfaudler turbines:

Low – medium viscosity: TBF, CBT, MSG, MXT, MFI

Medium – high viscosities: MSG, CBT, ANC, MFI

Dispersion / Emulsion (liquid/liquid)

Definition: Generation of a fine dispersion of two non-miscible liquids to enlarge the phase separation surface in order to intensify the mass transfer.

Recommended Pfaudler turbines: FBT for entire viscosity range.

Polymerization

Definition: Generating a flow pattern of liquids in order to allow for the formation of polymer particles and keep them in suspension until their complete conversion.

Recommended Pfaudler turbines: RCI for entire viscosity range, TBF for low viscosity applications and/or gentle treatment of the polymers.

Dispersion (liquid/gas)

Definition: Generate small bubbles of gas to maximaze reaction surface.

Recommended Pfaudler turbine: GST, FBT, CBT.

CFD – Computed Fluid Dynamics

For difficult agitator duties, yield improvement, maximizing energy inputs and/or refurbishing existing (not only glass-lined) agitators, Pfaudler provides optimization services through CFD analysis. Based on the end user’s process description, agitator tasks, product properties and/or sketches in case of existing equipment, Pfaudler will design the specific system and calculate data, such as:

- Flow pattern, directions, velocities

- Shear forces/shear constant surfaces

- Local and global power input

- Pressure gradients

- Temperature gradients/temperatures

- Solid suspension particle lines

- Heat flow

Resulting data, and computed pictures and videos are the tools for Pfaudler’s process engineers to design perfect agitator configurations.