Temperature measurement

Pfaudler - Glass-Lined & Alloy Systems

Technologies

Temperature - driving physical data in glass-lined equipment

In almost every chemical reaction, a follow up of the temperature of the processed media is needed. This is sometimes required to drive the process quality, for safety reasons, or just as an indication. Consequently, it becomes obvious that improving the performance of temperature measurement probes in glass-lined equipment is a guarantee of product quality, reproducibility. and safety. Pfaudler offers three glass-lined temperature probes:

- TMI probe

- TW probe

- T probe

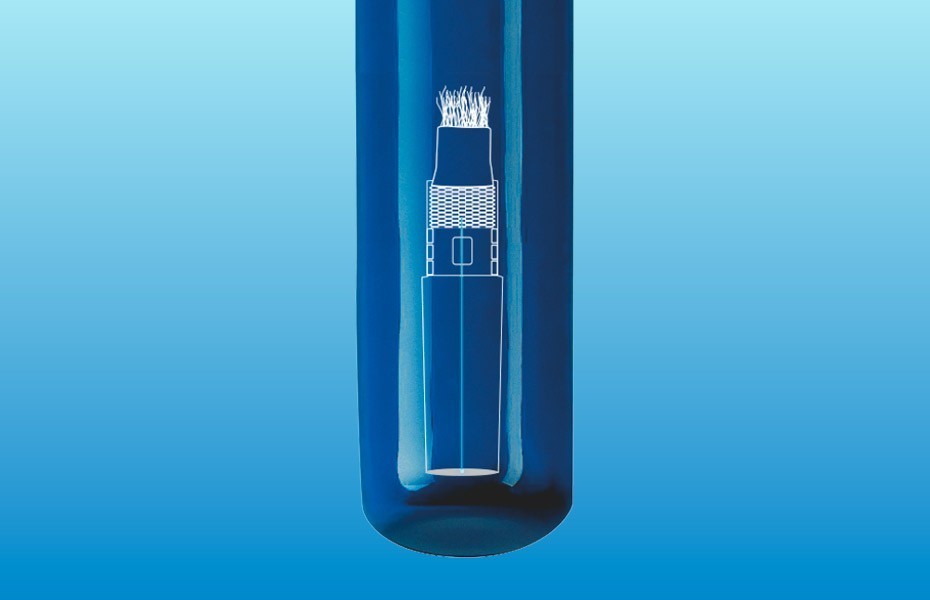

TMI probe

The TMI probe is the traditional probe for temperature indication. Up to 3 off Pt100 sensors are inserted in a thermowell, that is flange mounted on the vessel or reactor.

Despite all design precautions, the principle of inserting Pt100 sensors into glass-lined equipment has its disadvantages:

- long response times due to heavy metal masses around the probes;

- risk of drifting, due to exposure to any corrosive atmospheres or condensates in the thermowell;

- risk of breaking caused by vibrations.

Pfaudler recommends using the TMI probe only to monitor the temperature, and not to drive the process.

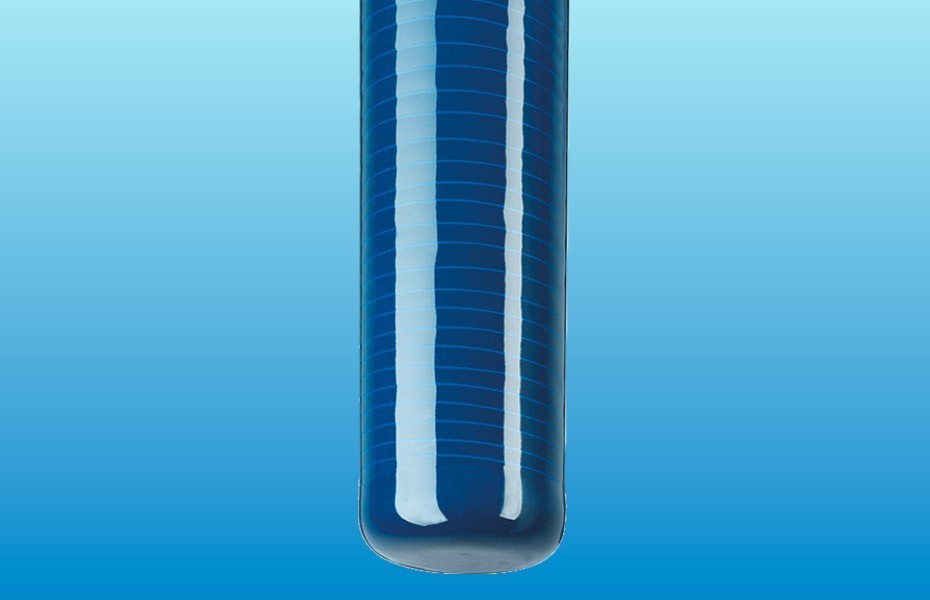

TW probe

The TW probe was launched by Pfaudler in the early 1980s. Pt100 sensors are fused into the glass layer of baffles or thermometer tubes. This type of design prevents all the disadvantages associated with the inserted Pt100, as explained above for the TMI type.

- Quick response time, roughly divided by 5, compared to inserted Pt100. The response time remains the same throughout its lifespan.

- No drifting, as the sensor is embedded in the glass; no diffusion of any gas in the glass, no contact with any condensates or rust.

- No recalibration necessary.

- No risk of breaking caused by vibrations.

Pfaudler recommends using the TW probe when temperature is a critical data of the process. Set points are followed up accurately, oscillations of energy supply curves are minimized, energy costs are optimized.

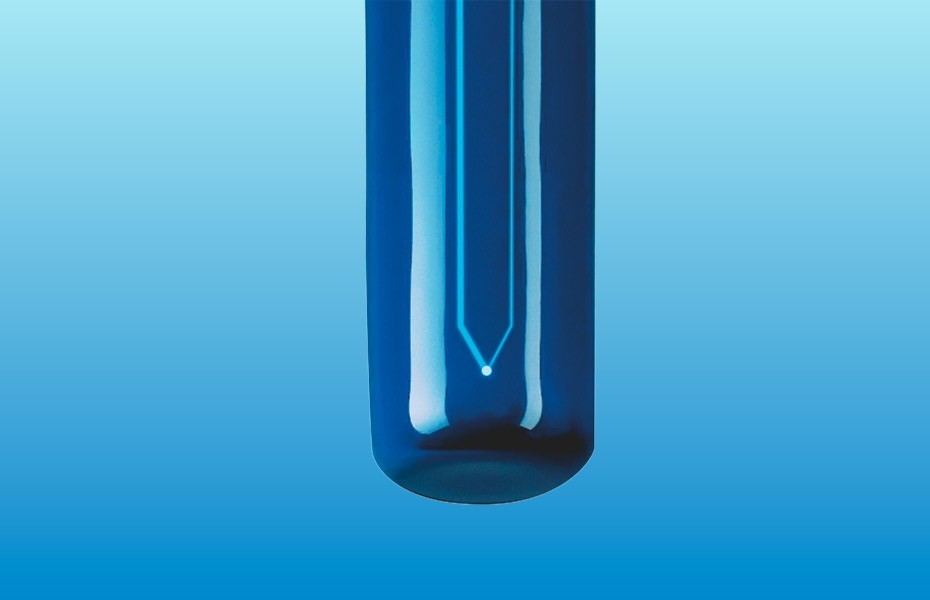

T probe

The T probe is an alternative to the TW probe, fused into the glass, with very similar features. Instead of being a Pt100, the sensor is a thermocouple. A glass point marks the measuring location. Benefits due to less space needed for installation:

- Up to 6 measuring locations possible on 1 probe carrier

- Simultaneous temperature measurements at different elevations in the reactor

- Combined on valve shafts with other sensors, such as corrosion monitoring

- Ring probe execution mounted between flanges, to measure the temperature in glass-lined or PTFE pipelines.

Pfaudler recommends using the T probe for the same purposes as the TW probe when, however, space for installation of a TW probe is not available.