Level Measurement Phase Separation Detection

Pfaudler - Glass-Lined & Alloy Systems

Technologies

Safe filling and emptying procedures

Glass-lined level sensors indicate the filling level in a storage tank or a reactor. The measurement can be continuous or a switch point. They are suitable for installation in glass-lined equipment, but also as a universal installation, with long-term stability and reliability and have the same surface properties as all other glass lined equipment.

Continuous level measurement

Pfaudler Levelpuls:

Glass-lined antenna combined with a microwave-emitting radar

- Extreme temperatures or pressures, gases, steam, or dust have no influence on the accuracy of the measurement

- Conical antenna protrudes only slightly into the vessel. Vessel volume can be fully utilized

Level switch on tubular probe carrier

Pfaudler Safety Swing:

Glass-lined vibrating fork, driven by an oscillator at its natural frequency. The frequency changes when the fork touches liquid. The change of frequency is detected, and a switching signal is generated.

- Can be installed in any position, horizontally, vertically or inclined

- Is used for functions, such as:

- Maximum or overfill level switch

- Minimum level switch

- Dry-run protection

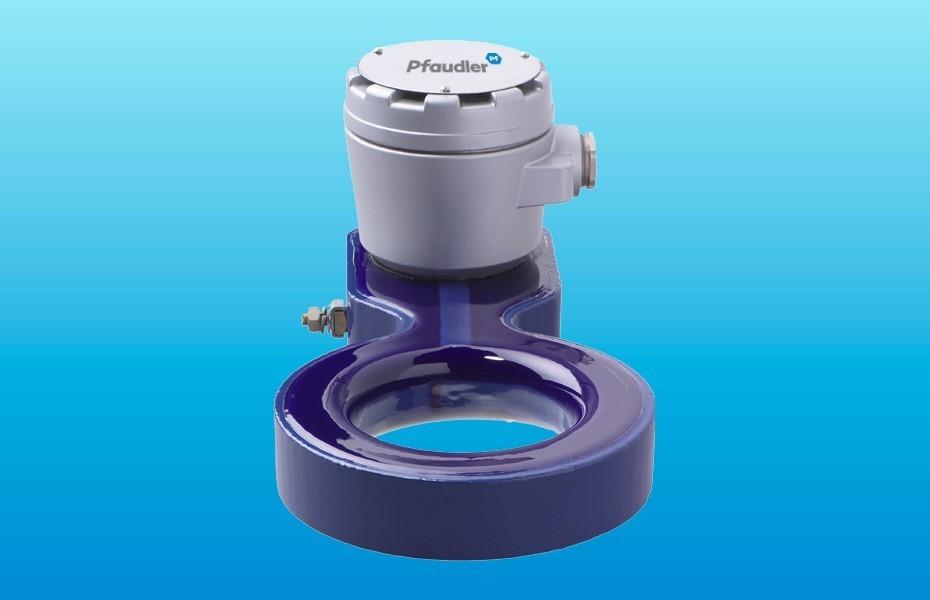

Level switch on ring probe carrier

Works according to the capacitor principle: the glass-lined sensor measures the dielectric constant of its environment. This constant is different in the presence of gas, acids or solvents.

- Is almost exclusively used for low level control at outlet of the reactor valve

- Detects full or empty vessels or lines – used to protect pumps

Safest measure for automatic phase separation detection

Many chemical reactions take place in a mix of organic and inorganic liquids. At the end of the batch, the fluid is decanted: two phases build up in the vessel – the lighter solvents at the top, the heavier acids at the bottom.

When emptying the reactor, the phases are separated. Since the acids are highly conductive and the solvents are isolators, a conductivity probe is generally used to detect the phase separation.

Due to the very important difference of the two conductivities, one is always out of the range of standard conductivity meters. A default signal for “out of range” is generated. The conductivity measurement is uncertain or unsafe.

Moreover, in the event of phases that are not well separated, with conductive liquid pockets in the organic phase, the measurement is wrong.

The Pfaudler FT capacitive sensor ring is the safe measurement for phase separation detection:

- The capacitance signal is available over the whole range of the dielectric constant of the fluids;

- No “error” signal is generated for a correct working measurement;

- The measurement is precise and fully reproductible.