Glass-Lined Columns

Pfaudler - Glass-Lined & Alloy Systems

Technologies

What is the purpose of a column in a chemical plant?

Columns are used in the chemical industry for many different mass transfer processes with the required separation accomplished through countercurrent flow of liquid and vapour inside the column.

Fractionation or distillation columns are used to separate various chemicals by the difference in their volatilities.

Stripper, absorber and scrubber columns are used to separate and purify products, recover unreacted raw materials or valuable product from waste streams or to remove hazardous chemicals from vent and waste streams to prevent chemical emissions and to meet environmental regulations.

Typical materials of construction for columns:

- a carbon steel, alloy, glass-lined, or fluoropolymer lined/coated shell, to ensure resistance to pressure or vacuum;

- internals, packings, trays, distributors to ensure chemical reactions.

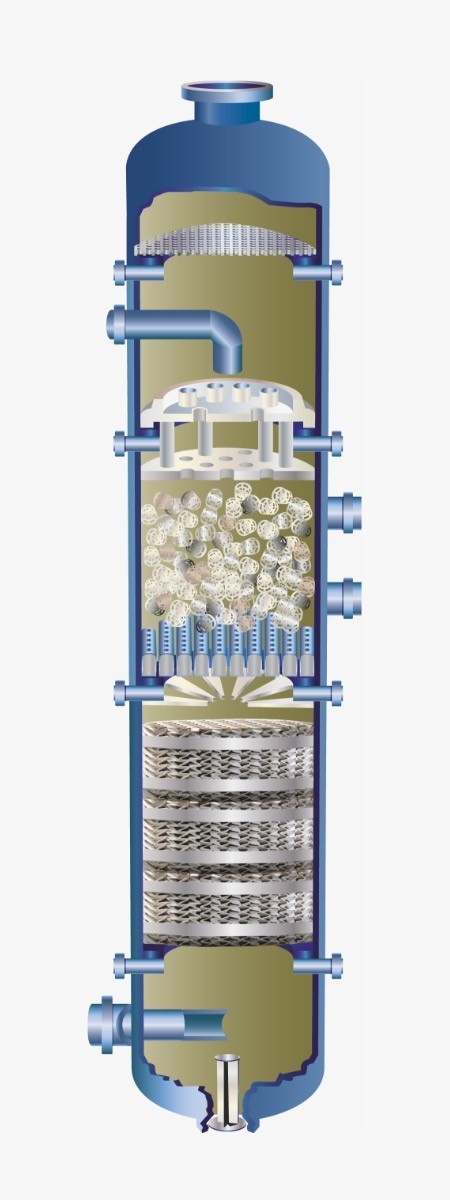

Glass lined columns and internals

Main features:

In presence of corrosive products, glass-lined columns offer required corrosion-resistant properties. The column shell is made of one or several glass-lined steel sections. The sealing at the body flanges of the different sections is using the Pfaudler Gasket System 3000 with UF3000 compound. The column shell can be supported either on brackets, rings, or skirts. Depending on the process, the different columns sections are jacketed or non- jacketed, insulated or non-insulated

Glass lined columns are frequently combined with internals in ceramic or PTFE from the Edlon product line, such as:

- Miscellaneous random packings

- Liquid distributors, redistributors

- Bed supports/ limiters

- Support trays/sieve trays

- Bubble caps

- Liquid injection pipes

To support the column internals, Pfaudler offers 2 designs:

- body flanges with donut rings: ideal for columns of rather small diameters;

- new support pin design: prevents use of donut rings and reduces leak potential. Recommended for large diameter columns.

A multitude of glass lined columns configurations: below a typical example.

There are as many column configurations as chemical processes. Columns are always customized to specific process requirements. Pfaudler adapts the column design to customers process specification. Below an example of a large column built for a major multinational chemist:

- Shell of 2,200 mm diameter x 22-metre height

- Design Pressure 10.0 Bar, g / Full Vacuum

- Design Temperature -24º / + 200º C

- Fabricated in 3 sections

- Customized nozzle location on top/bottom dish and cylindrical sections

- Support trays and distributor plates supported by pin support design

- Supports inside the column in tantalum clad rings

- Tolerances according to DIN 28007-2:2017-04 for column length and out of roundness

- In relation to column process requirements and contents: flange face flatness tolerance, as per the “fine” tolerance - Table 4 of the new DIN 28007-2:2017-04 standard

Complete Column System Design: much more than just manufacturing columns.

Pfaudler combines its pressure vessel, corrosion resistance and column internals Technologies with mass transfer engineering knowledge, expertise and experience at its Pfaudler Process Systems Department to design complete column systems with single-source responsibility for any corrosive, ultra-clean or ultra-pure chemical process.

These complete systems include the column plus:

- all ancillary equipment, instrumentation and piping completely assembled on structural steel modules or field fabricated

- project designed specifically for clients’ process through simulation with Aspen Hysis® or pilot testing

- proper system functionality to ensure all equipment, instruments and valves are arranged for ease of operation and maintenance