C-Baffle

Pfaudler - Glass-Lined & Alloy Systems

Technologies

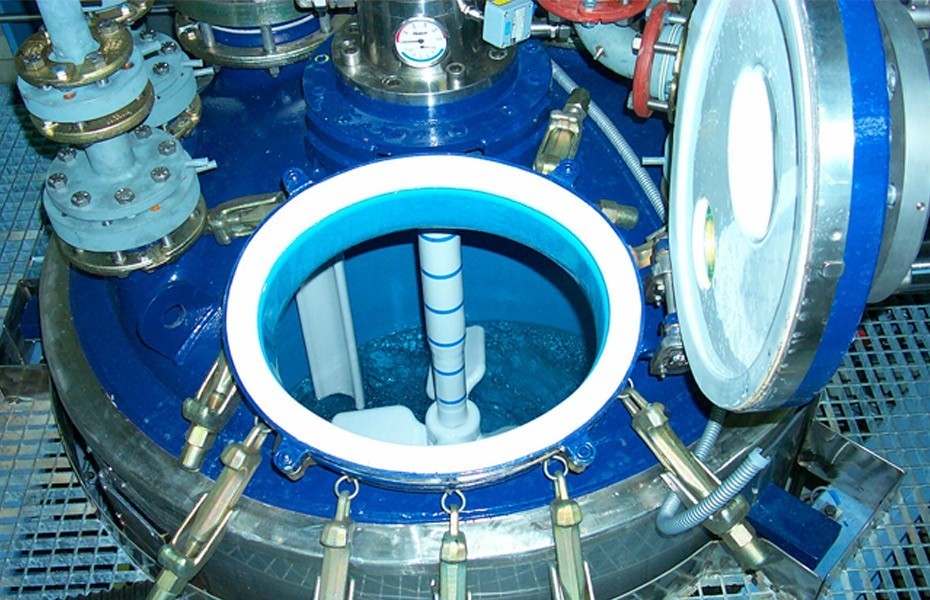

What is a C-baffle?

Baffles that have a concave shape, like a long tube cut in two parts along its axis, are called C-baffles. Their mechanical resistance is the same as standard beavertail baffles.

The flow direction enters the concave part of the baffle. Compared to a beavertail baffle, the flow resistance coefficient Cw is increased by more than 70%: Cw=2.3. This is the highest coefficient for any shape!

What are the features of C-baffles?

C-baffles are not only outstanding because of their high baffling performance, but also because of the additional features they provide to glass-lined agitating systems.

- Flexibility for reactors: Flange-mounted, can be easily installed or removed from a reactor, if the process needs a high baffling degree (C-baffle for dispersion, emulsion, suspension) or low baffling degree (beavertail for crystallization/no baffle for high viscosities).

- High baffling degree: One single C-baffle has a baffling degree of 0.69. Combined with a second one, the baffling degree becomes 0.9 – same baffling degree as three wall baffles.

- No nozzle “wasted” on the reactor: A process connection is available in the axis of the “C-baffle”. The “C-baffle” does not adversely affect the space for nozzles on the reactor.

Flexibility in maintenance: Any type of baffle generally has a shorter life span than the vessel in which it is installed.

- C-baffles, like beavertail baffles, are flange-mounted. They can be easily removed, re-glassed, and replaced or installed without dismantling the reactor.

- Temperature measurement sensors, without influencing the environment.

- Available with corrosion monitoring.

Reasons to refurbish an existing reactor with a C-baffle

C-baffles can be easily retrofitted on existing reactors when replacing an existing or worn beavertail baffle at the core of the process The benefits are multiple:

- Agitating power input may drastically increase productivity

- One more large nozzle made available for the process

- C-baffle axial nozzle is the ideal location for introducing liquids or solids above or below the surface. High turbulence under this nozzle provides quick diffusion in the reactive mass

- Enhancing the performance of an existing reactor with a low investment and at reduced installation costs.