Pipes, Fittings, Dip Pipes

Pfaudler - Glass-Lined & Alloy Systems

Technologies

Glass-lined internals, pipes, and fittings

The highly corrosive or very pure media handled in glass-lined vessels or reactors must be transferred from one vessel to another within pipelines having the same corrosion resistance performance as the glass-lined vessels.

Pfaudler offers a wide range of pipes, fittings, and dip pipes to resolve issues of corrosive media transfers.

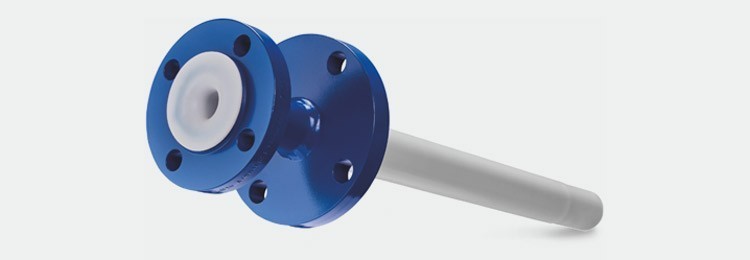

Dip Pipes

Glass-lined dip pipes are pipes, glassed internally and externally, fitted on nozzles of reactors, generally flanged on the top dish. They are used inside the reactor to:

- introduce a liquid into a reactor under the filling level;

- introduce a gas into a reactor, under the filling level, often close to the agitator, for quick gas dispersion; such dip pipes may be bended to the optimal introduction point for a quick dispersion.

- through short dip pipes, introduce a liquid or a gas into a reactor above the filling level, while preventing the media from coming into contact with the nozzle wall;

- introduce a liquid into a reactor above the filling level, through a bended dip pipe, in order to direct the flow towards the wall and prevent splashing on the surface;

- prevent installing an outlet nozzle, for safety reasons, and empty the reactor via a long dip pipe by overpressure in the vessel.

Dip pipes exist in many sizes: standard, from DN25/L300 to DN250/ L3600 mm, or larger. If non-customized, they can be available almost immediately.

Here are only some examples of the use of dip pipes. Many other requirements for dip pipes may exist. Pfaudler’s engineering teams are always attentive to the requirements of their clients and happy to search with them for the most suitable and appropriate solution.

A very similar dip pipe product range is available as PTFE lined equipment with the Pfaudler Edlon brand.