Cleaning-in-Place Technology

Pfaudler - Glass-Lined & Alloy Systems

Technologies

Why use Cleaning-in-Place?

CIP or Cleaning-in-Place has become a very important technology. A high availability of production plants is a key issue for today’s frequent production changes in reactors and vessels.

Pfaudler offers a large range of technical solutions for a quick and thorough CIP for glass-lined reactors and vessels.

Pfaudler Pharma Glass (PPG)

Cleaning glass-lined reactors is an issue in a production process. Pfaudler recommends the use of its patented PPG Glass. Three of its differentiating four properties vs. other glass focus on the CIP:

- Its light blue colour allows bright insight in the vessels and, thanks to its high contrast to white products, eventual residues left on the wall after cleaning can be easily identified.

- The smoothness of the surface allows for quicker cleaning, since residues may stick less to the wall.

- The increased chemical resistance vs. standard glass in the alkaline range allows cleaning at higher temperatures without risking corrosion of the glass, therefore, shortening the cleaning process.

.jpg)

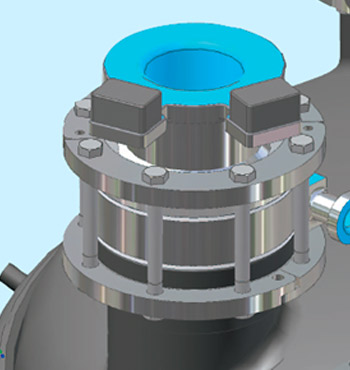

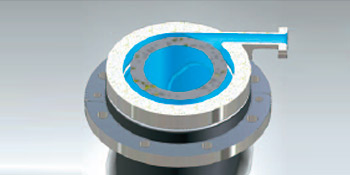

Pfaudler CIP ring

The glass lined Pfaudler CIP ring is designed for cleaning critical zones, such as the gap between a nozzle neck and the external wall of an insert, like a baffle or a dip pipe. A tangential injection of a cleaning media results in a tangential flow along the walls, which then get cleaned.

CIP lances

CIP lances, consisting of a lance and a cleaning nozzle, made either of PTFE or sometimes of Hastelloy, can be permanently attached to the vessel during the process or be removable. Generally located at 120° on the half radius of the upper dish of reactors, they can nevertheless be located at a specific position, defined by a dedicated CIP study.

CIP of manhole nozzles

The upper edge of the manhole nozzle (the edge on the smallest radius of the upper dish of the vessel) is generally difficult to clean, and it is potentially difficult to reach with cleaning lances only installed on the upper dish. Pfaudler proposes two solutions to safely clean this area in combination with a Fillook manhole cover:

A portable, removable CIP lance, to be attached without tooling, on a Pfaudler quick-opening Fillook manhole cover. Since this CIP lance is not made to remain in the process, no special corrosion- resistant materials are required. It is installed and removed very quickly through four thumbscrews – without any tooling.

One or two cleaning lances attached to the Pfaudler Fillook Multiport manhole cover. The two additional nozzles in DN50, along with the two Glasslook sight glasses (of which one on a Fillook cover) on the DN500 or DN600 manway covers, can be used for a number of applications without occupying reactor nozzles, such as for instance cleaning lances, but also pressure gauges or other small accessories.

Validating the cleaning procedure

In special cases upon request of the end user, cleaning efficiency may be validated at the manufacturer’s premises. The so-called “Riboflavin-test” has proven its worth in this case. The vessel is “contaminated” with a Riboflavin solution. The predefined cleaning steps are performed. After these steps have been completed, any residual Riboflavin is fluorescent under UV light.

Before test

After test