Ultra-high Purity Coatings

Edlon - Fluoropolymers

Technologies

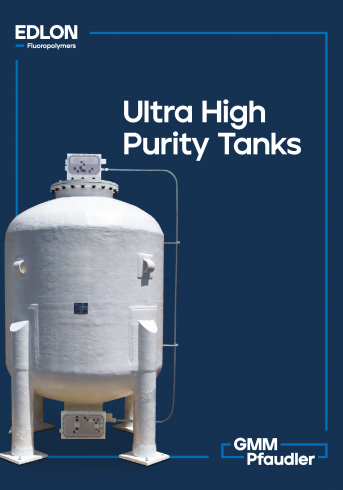

Ultra-high purity mineral acids and bases form the core of wet fabrication processes. While the production of these chemicals is carried out using well-established processes, a demand for high purity requires a careful control of the material selected for linings and coatings used to passivate equipment, such as distillation columns, condensers, and heat exchangers, as well as storage tanks. To produce such backbone chemicals with ppt purity levels, fluoropolymers materials are the materials of choice in construction.

Edlon® PFA Perfluoropolymer Engineered Coatings are the standard adopted for use in photoresistant and etchant fluid management.

Chemicals used in the fabrication of electronic devices, such as those for cleaning and finishing agents for wafers, various lithographic patterning processes, and chemicals for printed electronics, must be produced with purity levels in the order of part per trillion. To maintain this level of ultra-high purity, coatings are fluoropolymers coatinf is used to significantly reduce the level of metal cations leached into the chemicals from the surface of the containers. Trace impurities can heavily impact the performance of material.

To address these requirements, Edlon® specifically developed its unique PFA formulation for an electrostatically applied thick coating that is sought after by leading photoresist and etchant manufacturers. Both in-house and independent laboratory testing have verified that the PFA SC-7005™ coating system is unparalleled in its ability to maintain ppt concentrations of metal cations. That is why it is now the material of choice for reactors and tanks used in the production and storage of ultra-high purity chemicals.