Fluoropolymer Lined Columns

Edlon - Fluoropolymers

Technologies

Over the past 50 years, Edlon designed thousands of columns in the widest variety of industrial applications

Edlon has a broader spectrum of corrosion-resistant materials to choose from than any other mass transfer equipment supplier. Edlon offers coatings and linings in a full range of thicknesses, including loose liners and glass-backed liners bonded to steel with proprietary adhesives. Such diversity, particularly with fluoropolymers, allows us to explore alternatives until we find the best solution.

Our design capabilities allow us to match overall column design to specific chemical processes, taking into account column size, throughput, tray hydraulics, packing properties, heating and cooling demands, as well as corrosion resistance.

A Multitude of Fluoropolymer lined Column Configurations:

Edlon provides bonded liners, loose liners and coatings in a variety of chemically inert materials that feature a smooth, nonstick surface and maximum heat, permeation and corrosion resistance.

Standard carbon steel shells, stainless steel or highly alloyed steel grades are available and produced in varying thickness and code designs.

Support brackets and vent couplings can be added to further customize any design.

A range of fluoropolymer materials that offer superior performance characteristics in a wide range of operating conditions. Please consult Edlon for chemical resistance and temperature considerations in selecting the proper materials.

Liner thickness is based on application requirements.

Smooth Bonded Liners, Loose Liners and Coatings

Edlon provides bonded liners, loose liners and coatings in a variety of chemically inert Fluoropolymer materials that feature a smooth, nonstick surface and maximum heat, permeation and corrosion resistance.

Lining can be made from

- modified PTFE

- PFA

- FEP

- ECTFE

- PVDF

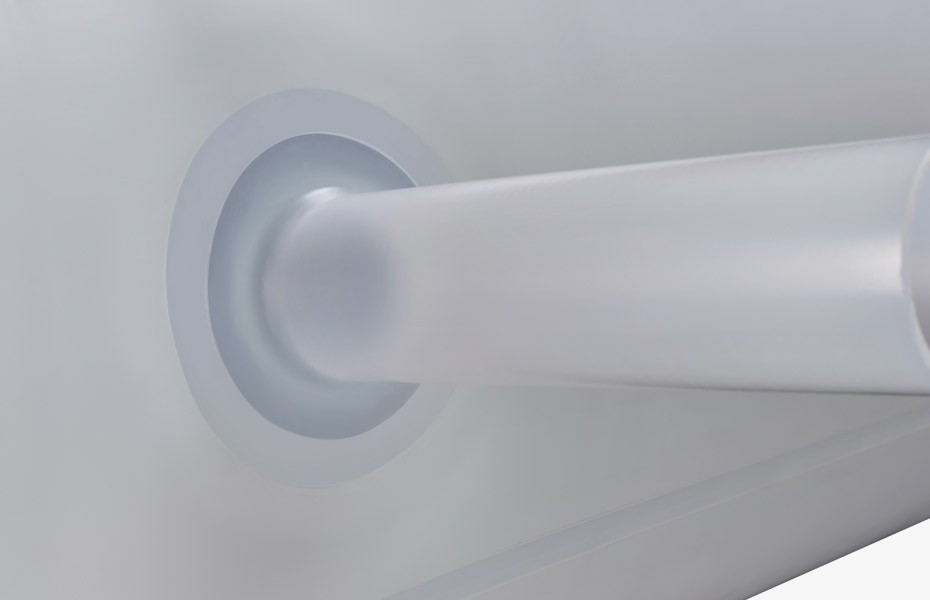

- Machine fusion welded nozzle-no weld in corner

- Weld area outside of high stress 90° radius

- Full penetration weld

- No change in liner thickness allows joint to flex minimizing stress

- Easier to inspect weld for defect

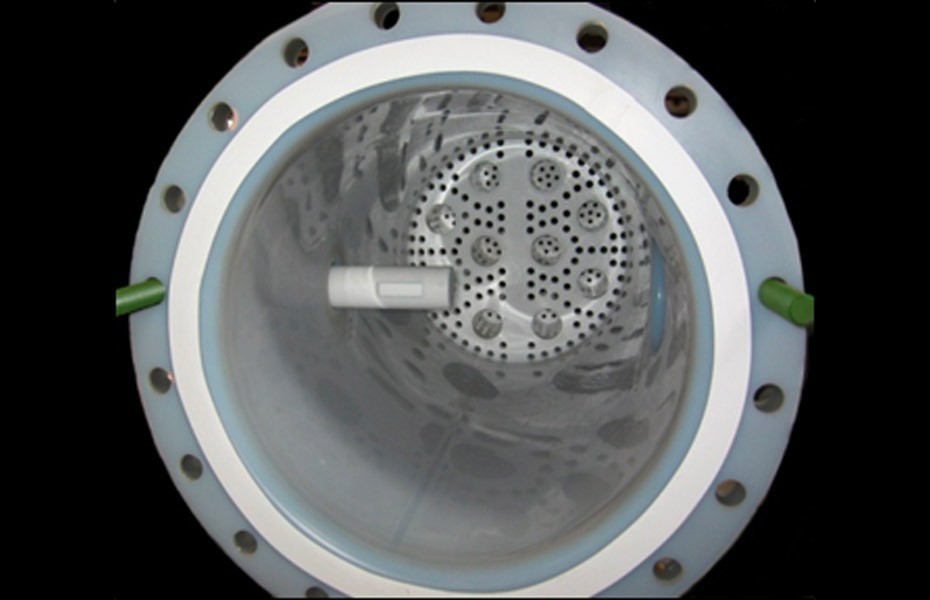

Nozzle Design

Edlon not only fusion-welds liner sheets together, but also utilizes this technique to install nozzles into liners. Edlon’s fusion-welded nozzle seams enable us to offer low stress nozzle designs to eliminate some of the most common failure modes, such as vapor permeation through a weak air weld. Fusion-welded nozzle seams significantly reduce stress risers and the risk of stress-cracking that is normally associated with air welds in these critical areas.

Smooth and Crevice-Free Welds

Edlon’s Proprietary Fusion Welding Technology ensures fast, smooth, high-strength indiscernible seams. Pure-FusionTM seams are produced in a controlled environment and all Pure-Fusion liners are formed from unpigmented resin spark tested at 20,000 volts.

No steps or crevices are created between liner sheets for metal ion contamination, bacterial growth, or other impurities that could collect and affect your process and eventually cause it to fail.

Edlon Pure-FusionTM Fluoropolymer-lined Columns

| Property | Property |

|---|---|

| Application | Highly Corrosive Chemical Mediums Ultra-High Purity Electronic Grade Chemicals |

| Design Codes and Configuration | ASME, ASME (U-Stamp), AD-2000 Merkblatt, RTP-1 (for FRP/Dual laminates) Shell: Carbon or Stainless Steel or Highly alloyed Steels or FRP Lining: Bonded or loose lining made with Pure-Fusion™ Welding Technology |

| Head Geometry | Flat, Conical and Dished (various designs) High Integrity Thermoformed and Pure-Fusion™ fabricated in one piece (specifically excluding manual hot-gas /air-welding) |

| Thickness | Range from 60mil to 180mil (1.5mm to 4.7mm) |

| Lining Material | PTFE and Modified PTFE, PFA, FEP, ECTFE and PVDF |

| Diameters Lengths | Up to 10-ft (3000mm) Any permissible – however, consult with Edlon on best length depending on the application temperature |

| Temperature range | up to 200°C (depending on other application parameters and chemistry) |

| Design Pressure | 0 / 250 psig (0/ 17 barg) (depending on application temperature) |

| Permeation management system | Edlon designed vent couplings / Design with Counter-vacuum system available |

| Design Features | Reliable and Reproducible Pure-Fusion™ welded Fluoropolymer lining Special LowStress™ design for applications at high temperatures Vacuum Support Systems can be provided depending on type and level of operating vacuum levels. (optional) Dual lining/Coating System: Metal Shell can be coated with a thick Fluoropolymer coating as a secondary barrier behind the loose lining – specially for ultra-high purity and very aggressive applications. |

| Nozzle connection | Pure-Fusion™ welded Fluoropolymer lining Special LowStress™ design for applications (Stress relieved lining – critical for nozzle lining) |

| Column Internals | Column designed to support column internals by using PFA-lined support rings bolted to body flanges. Column Internals can be designed in one-piece or modular to allow for easy field installation (specifically for large diameter columns) |