Corrosion Resistant Columns

05 July 2016

Corrosion Resistant Columns

Columns are used in the chemicals industry for many different mass transfer separation processes. Fractionating or distillation columns are used to separate various chemicals by the difference in their volatilities. The chemical unit operations of distillation, fractionation, or stripping are used to separate and purify products. Stripper, absorber and scrubber columns are used to separate and purify products, recover valuable product or unreacted raw materials from waste streams or to remove hazardous chemicals from vent and waste streams to prevent chemical emissions and to meet environmental regulations.

In 1884, Pfaudler invented the technology of corrosion resistant, glass-lined steel (Glasteel®) and is the leader still today in this technology. In addition to chemical reactors and storage tanks, Pfaudler also designs and fabricates glass-lined steel columns. Our Pfaudler Edlon division pioneered the use of fluoropolymer technologies to the chemicals industry, and in addition chemical tanks, also designs and fabricates fluoropolymer-lined columns.

Pfaudler’s process engineering group, established in the 1950’s, has a team of chemical process engineers dedicated to the design of distillation, fractionation, scrubber, and absorber columns for corrosive applications. Our group team designs and manufactures internal components for alloy columns and complete column process systems.

Pfaudler combines these technologies, resources and expertise to design a complete column “system”, with single-source responsibility, for any corrosive chemical process.

- Pfaudler mechanical engineers are certified to design and build your column shell per all major global pressure vessel codes, including ASME, PED, DIN, TUV, AD 2000, TEMA, SELO and GB150. Pfaudler designs and fabricates glass-lined or fluoropolymer lined columns to safely contain hazardous chemicals at operating conditions.

- Pfaudler chemical engineers utilize Apentech HYSYS software to simulate any chemical process and design the column internals necessary to affect the necessary separation.

- Pfaudler designs, fabricates and supplies all the column internals including the packing, supports, and distributors in fluoropolymer, glass-lined steel, or ceramic materials of construction in structured or random form.

Our start-of-the-art process test facility which includes multiple columns with which we process customer materials to confirm performance of our technologies for each specific process and collect data to design a commercial scale facility. Please see the video describing our test facility on our website.

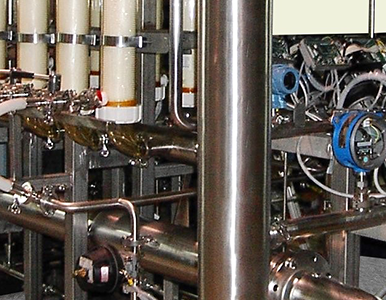

Pfaudler also designs and fabricates complete chemical processes involving columns. These systems include not only the column “system” but all the ancillary equipment, piping, instrumentation and controls to provide a complete Engineered Solution for your process needs.

Pfaudler has thousands of installed columns in hundreds of different applications globally. Contact Pfaudler and work with us to design your column to improve yield and purity, recover product and raw materials to reduce costs and strip hazardous chemicals to prevent environmental emissions.