"CIP" cleaning of the critical zones of a glass-lined reactor

03 August 2017

"CIP" cleaning of the critical zones of a glass-lined reactor

Pfaudler CIP cleaning (Cleaning in Place) technology for nozzles, i.e. cleaning a chemical plant without taking it apart, has become increasingly important in recent years. Formerly, operators could afford longer downtime to clean their plants, whereas high plant availability has nowadays become a key issue given today´s frequent product changes. This does not only apply to the production of pharmaceutical agents. The chemical industry also calls for efficient solutions for cleaning devices and systems.

Pfaudler offers technical solutions for CIP cleaning glass-lined reactors quickly and thoroughly. One of these solutions is the Pfaudler CIPring.

The CIPring offered by Pfaudler is a user-friendly tool to thoroughly clean even the “critical” zones of a glass-lined reactor – the nozzle necks and sight glasses.

Due to the requirements of the glassing process, the nozzles of glass-lined devices are always swaged and thus relatively long.

For example, if dip pipes or baffles are installed in nozzles, the combination of the swaged nozzle and the built-in part form a geometry that is difficult to access. Incrustation and product residues are very difficult or even impossible to remove from this narrow gap.

Even sight glasses are difficult to clean from the inside due to the nozzle neck when they are mounted on a reactor nozzle.

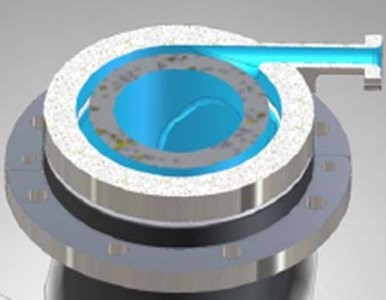

The CIPring is a ring-shaped component that is coated with highly resistant Pfaudler PharmaGlass (PPG) inside. The ring is manufactured in nominal diameters (DN 65 to DN) 400 and has a DN 25 nozzle attached for introducing a rinsing fluid tangentially.

If the flow is sufficient, the tangential nozzle provides for a highly kinetic rotary flow, which ensures the contaminated areas within the nozzle and on the built-in part are suitably cleaned.

For sight glass cleaning, a PTFE ring is firmly installed in the glass-lined CIPring, which redirects the tangential flow into a shower-shaped jet onto the sight glass.

Click here to watch the video on the Pfaudler YouTube channel

Contact Pfaudler today to learn more