CFD in Mixing Technology

02 July 2016

CFD in Mixing Technology

Numerical fluid mechanics (Computational Fluid Dynamics, CFD) is an approved method of fluid mechanics. CFD is commonly used in applications for the automotive and aircraft industries; it is also used in the process and mixing industries.

The goal is to solve flow related questions with numerical methods. The equations are mostly according to Navier-Stokes, Euler or potential based.

CFD offers the possibility to solve problems and to show results with demonstrative pictures and videos. The user will get results like flow velocities and directions, shear forces, local energy dissipation, mechanical power input, heat transfer coefficients, local pressure distribution, suspending possibilities as an abstract of the most important results. CFD is a fast and economic method compared to lab experiments or field tests. The influence of geometrical variations like modified blade pitch, width of blades, or new customized turbine designs can be examined to decide if the variations are beneficial to the process.

Also problems normally found during operation of equipment (for example, cavitation damage) can be analyzed and explained to prevent similar damage in future.

Additionally, CFD is very helpful when reviewing retro-fit projects such as upgrading from outdated mixing systems or baffles to current technology offerings like Cryo-Lock™. It allows for validation of more effective or energy saving designs. A large number of process related questions can be analyzed prior to the start of any manufacturing of equipment.

Pfaudler is successfully using CFD related to mixing/process technology and heat transfer. We have practical experience to verify mixing systems and complete feasibility studies. We have data bases with all standard equipment such as turbines, baffles and vessel geometries available allowing us to produce 3D-models (the base of each CFD calculation) in a short period of time. All results are included in a final report with suggestions, recommendations, pictures and video clips. We are offering services beginning with the CFD analysis through the delivery of mixing system, all from a single source.

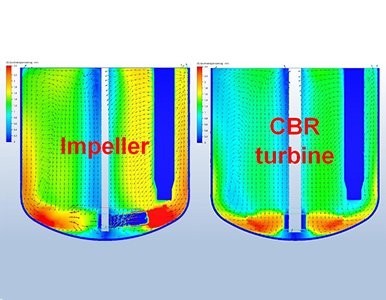

Case example: Replacement of a damaged Impeller style agitator by a CBR turbineThe intention of the CFD is a confirmation of changeability of impellers. In this case, we set out to show that the CBR style agitator will deliver comparable results at given process conditions. The idea was to prove that flow direction and energy input results of the two different style impellers are very close and that the risk of process deviations will be low. A speed modification of the existing drive was not desired. The calculation was based on parameters like density and viscosity.

Results:

Velocity distribution, vertical cut across the reactor. See YouTube channel

As shown in the result pictures the deviations are small. Based on the comparison the change of the mixing system was realized and the CFD results could be confirmed by the customer/operator after installation of the new mixing system.